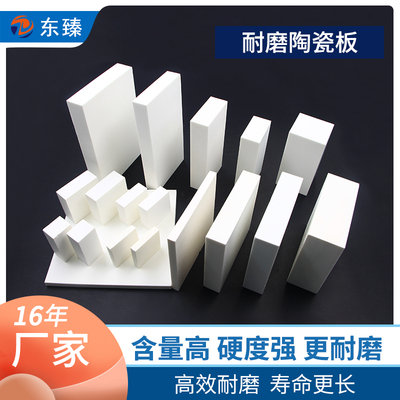

供应焊接氧化铝陶瓷 *陶瓷板

<*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体"> 陶瓷板规格种类(带孔的12<*n style="font-family:宋体">元每公斤,不带孔的<*n style="font-family:Calibri">11<*n style="font-family:宋体">元每公斤)

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">陶瓷板150*100*6<*n style="font-family:宋体">(<*n style="font-family:Calibri">18<*n style="font-family:宋体">元每公斤);<*n style="font-family:Calibri">150*100*8<*n style="font-family:宋体">(<*n style="font-family:Calibri">15<*n style="font-family:宋体">元每公斤);<*n style="font-family:Calibri">150*100*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*100*12<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*100*15<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*100*20<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*100*25<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*100*30

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">陶瓷板100*100*6<*n style="font-family:宋体">(<*n style="font-family:Calibri">18<*n style="font-family:宋体">元每公斤);<*n style="font-family:Calibri">100*100*8<*n style="font-family:宋体">(<*n style="font-family:Calibri">15<*n style="font-family:宋体">元每公斤);<*n style="font-family:Calibri">100*100*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*100*12<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*100*15<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*100*20<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*100*25

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">陶瓷板150*50*6<*n style="font-family:宋体">(<*n style="font-family:Calibri">18<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤);<*n style="font-family:Calibri">150*50*8<*n style="font-family:宋体">(<*n style="font-family:Calibri">15<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤);<*n style="font-family:Calibri">150*50*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50*12<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50*14<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50*15<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50*20<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50*25<*n style="font-family:宋体">;

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">陶瓷板120*80*6<*n style="font-family:宋体">(<*n style="font-family:Calibri">18<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤);<*n style="font-family:Calibri">120*80*8<*n style="font-family:宋体">(<*n style="font-family:Calibri">15<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤);<*n style="font-family:Calibri">120*80*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">120*80*12<*n style="font-family:宋体">;<*n style="font-family:Calibri">120*80*15<*n style="font-family:宋体">;<*n style="font-family:Calibri">120*80*20

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">陶瓷砖90*60*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">90*60*12

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">燕尾卡槽陶瓷100*60*10<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*60*11<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*60*12

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">球面陶瓷75*75*20+5<*n style="font-family:宋体">;<*n style="font-family:Calibri">80*80*20+5

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">卡槽35*80*10<*n style="font-family:宋体">(<*n style="font-family:Calibri">15<*n style="font-family:宋体">元每公斤)

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体">T<*n style="font-family:宋体">型陶瓷<*n style="font-family:Calibri">150*50/47*10;150*50/47*12<*n style="font-family:宋体">;<*n style="font-family:Calibri">150*50/47*15<*n style="font-family:宋体">;<*n style="font-family:Calibri">100*40/37*10<*n style="font-family:宋体">;

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">弧形陶瓷板,旋流器板(18<*n style="font-family:宋体">元每公斤)

- <*n style="font-size:14.0000pt"><*n style="font-family:宋体">95<*n style="font-family:宋体">瓷*陶瓷板<*n style="font-family:Calibri">14<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体"> 12.互锁互压陶瓷<*n style="font-family:Calibri">40*50*6-12<*n style="font-family:宋体">,<*n style="font-family:Calibri">50*60*6-12<*n style="font-family:宋体">,带孔的单价是<*n style="font-family:Calibri">20<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤,不带孔的<*n style="font-family:Calibri">18<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤,<*n style="font-family:Calibri">18*18*5<*n style="font-family:宋体">单价<*n style="font-family:Calibri">25<*n style="font-family:宋体">元<*n style="font-family:Calibri">/<*n style="font-family:宋体">公斤

<*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">*陶瓷板说明

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">1<*n style="font-family:宋体">、主要成分:<*n style="font-family:Calibri">AL2O3<*n style="font-family:宋体">。<*n style="font-family:Calibri">

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">2<*n style="font-family:宋体">、产品种类:根据<*n style="font-family:Calibri">AL2O3<*n style="font-family:宋体">含量的百分比分为<*n style="font-family:Calibri">92<*n style="font-family:宋体">瓷、<*n style="font-family:Calibri">95<*n style="font-family:宋体">瓷、<*n style="font-family:Calibri">96<*n style="font-family:宋体">瓷、<*n style="font-family:Calibri">99<*n style="font-family:宋体">瓷等。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">3<*n style="font-family:宋体">、产品硬度:洛氏硬度<*n style="font-family:Calibri">HRA<*n style="font-family:宋体">≥<*n style="font-family:Calibri">86<*n style="font-family:宋体">。硬度仅次于金刚石,远远超过*钢和不锈钢的*性能。*性相当于锰钢的<*n style="font-family:Calibri">300<*n style="font-family:宋体">倍,高铬铸铁的<*n style="font-family:Calibri">190<*n style="font-family:宋体">倍。<*n style="font-family:Calibri">

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">4<*n style="font-family:宋体">、主要用途:主要用于风机、磨煤机、粉磨机、选粉机、粗细粉分离器、高低温烟道风道、除尘管道、煤粉输送管道、溜槽、落料管、旋流器、离心机、浮选槽、矿渣磨、<*n style="font-family:Calibri">V<*n style="font-family:宋体">选机、再循环风管道、物料输送管道、尾矿管道、渣斗、灰斗、振动筛等*工况。<*n style="font-family:Calibri">

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">5<*n style="font-family:宋体">、产品密度:密度值一般都大于<*n style="font-family:Calibri">3.6g/cm3<*n style="font-family:宋体">,不到钢铁密度的一半,可减轻设备的载荷。<*n style="font-family:Calibri">

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">6<*n style="font-family:宋体">、主要规格:<*n style="font-family:Calibri">

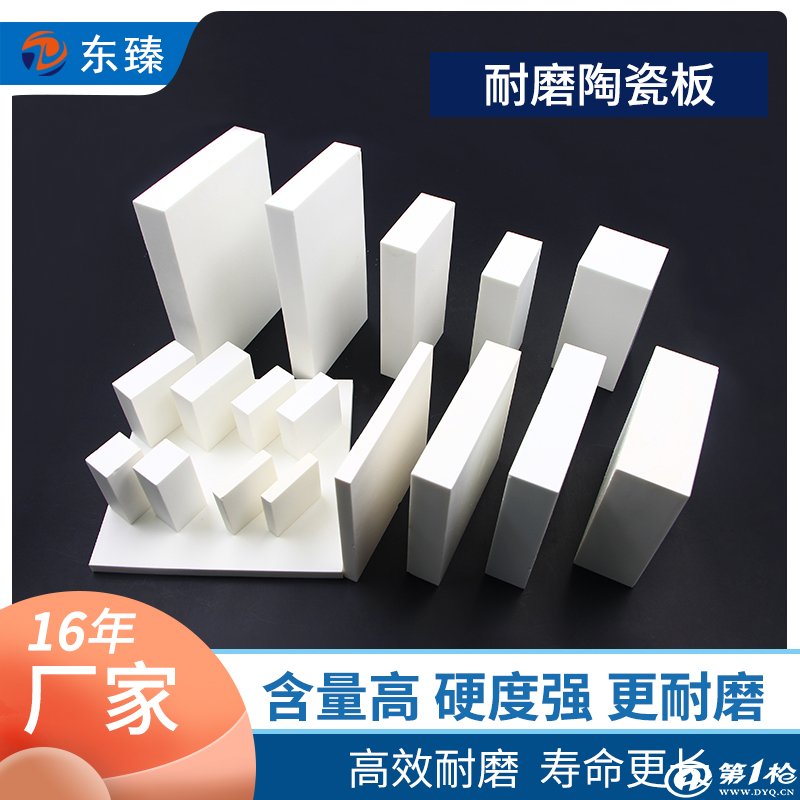

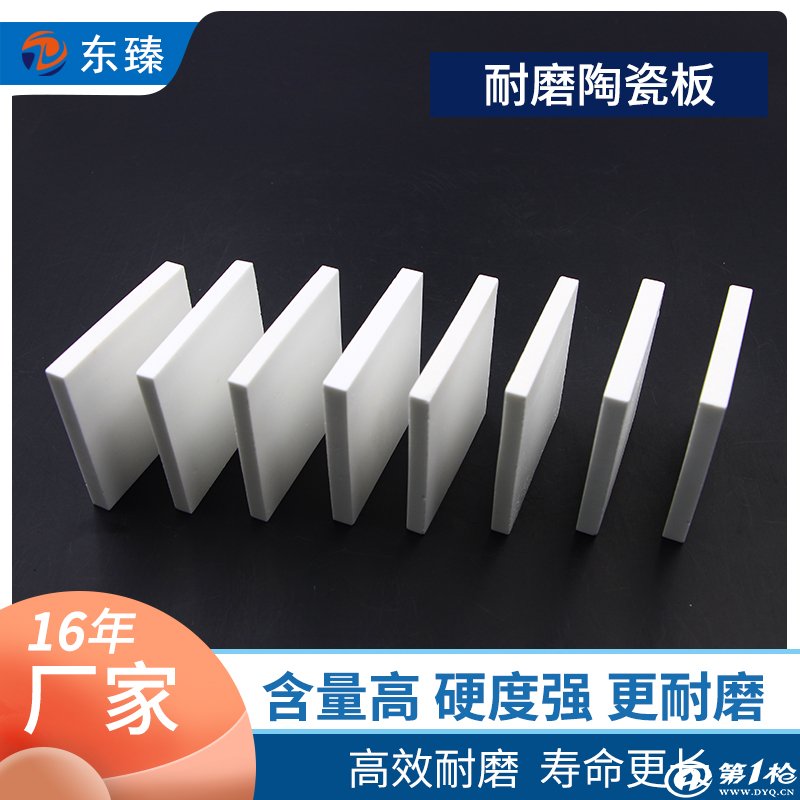

<*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">外形尺寸有长方形、正方形、梯形、条形、弧形

<*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">厚度一般为6mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">8mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">10mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">12mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">15mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">16mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">18mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">20mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">25mm<*n style="font-family:宋体">、<*n style="font-family:Calibri">30mm<*n style="font-family:宋体">等多种。

<*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">外形尺寸一般为50*50<*n style="font-family:宋体">,<*n style="font-family:Calibri">100*50<*n style="font-family:宋体">,<*n style="font-family:Calibri">150*50<*n style="font-family:宋体">,<*n style="font-family:Calibri">120*80<*n style="font-family:宋体">,<*n style="font-family:Calibri">100*80<*n style="font-family:宋体">,<*n style="font-family:Calibri">100*100<*n style="font-family:宋体">,<*n style="font-family:Calibri">150*100<*n style="font-family:宋体">等规格

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">7<*n style="font-family:宋体">、外观质量要求:除对<*n style="font-family:Calibri">AL2O3<*n style="font-family:宋体">含量要求外,还要求陶瓷板表面平整,无黑点,光滑不粗糙,色泽均匀,边角方直。

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">8<*n style="font-family:宋体">、通用名称:高铝衬板,*陶瓷板,陶瓷板,氧化铝衬板,管道衬板,陶瓷衬板,陶瓷衬砖<*n style="font-family:Calibri">

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">9<*n style="font-family:宋体">、主要应用行业:火电、钢铁、冶炼、机械、煤炭、矿山、化工、水泥、港口码头等企业的输煤、输料系统、制粉系统、排灰、除尘系统等一切磨损大的机械设备上

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">10<*n style="font-family:宋体">、*陶瓷板特点:<*n style="font-family:Calibri">

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">A.<*n style="font-family:宋体">*陶瓷硬度大:<*n style="font-family:Calibri"> <*n style="font-family:宋体">其洛氏硬度为<*n style="font-family:Calibri">HRA80-90<*n style="font-family:宋体">,硬度仅次于金刚石,远远超过*钢和不锈钢的*性能,*陶瓷衬片*性能好<*n style="font-family:Calibri">

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">B<*n style="font-family:宋体">、*陶瓷重量轻<*n style="font-family:Calibri"> <*n style="font-family:宋体">:其密度为<*n style="font-family:Calibri">3.6g/cm3<*n style="font-family:宋体">,不到钢铁密度的一半,可大大减轻设备承重载荷。<*n style="font-family:Calibri">

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">C<*n style="font-family:宋体">、*陶瓷耐热性能好:*陶瓷衬片一般可以耐<*n style="font-family:Calibri">1400<*n style="font-family:宋体">度,采用耐热胶或者采用焊接方式粘贴在设备内壁,在<*n style="font-family:Calibri">750<*n style="font-family:宋体">℃下可长期运行不脱落。<*n style="font-family:Calibri">

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">11<*n style="font-family:宋体">、包装方式:纸箱,一般一箱的重量在<*n style="font-family:Calibri">20KG-25KG<*n style="font-family:宋体">,一吨以上可以打托盘,

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">12<*n style="font-family:宋体">、臻牌*陶瓷质量承诺:我们的*陶瓷衬片原料为中铝或者山铝的高等级产品,采用干压方式成型,经过隧道窑<*n style="font-family:Calibri">1500<*n style="font-family:宋体">度高温烧制而成,烧制出的陶瓷衬片颜色均匀,有玉的质感,从外观看表面平整无粘连,无黑点原料粉杂质含量少),通过<*n style="font-family:Calibri">ASTM65<*n style="font-family:宋体">试验合格后才可以出厂<*n style="font-family:Calibri"> <*n style="font-family:宋体">。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">13<*n style="font-family:宋体">、*陶瓷板的质量鉴定方法:<*n style="font-family:Calibri">

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">A.<*n style="font-family:宋体">高质量的*陶瓷板表面平整,无黑点,光滑不粗糙,色泽均匀;

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">B.<*n style="font-family:宋体">测密度,氧化铝含量可以通过测密度来推算<*n style="font-family:Calibri"> <*n style="font-family:宋体">;

<*n style="font-size:10.5000pt"><*n style="font-family:宋体">C.<*n style="font-family:宋体">做*实验,用喷砂机在压力<*n style="font-family:Calibri">4.0kg/cm3,<*n style="font-family:宋体">距离<*n style="font-family:Calibri">50mm,<*n style="font-family:宋体">喷射角度<*n style="font-family:Calibri">45<*n style="font-family:宋体">度,时间在<*n style="font-family:Calibri">60<*n style="font-family:宋体">分钟内测磨耗。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:14.0000pt"><*n style="font-family:宋体"><*n style="color:#000000"><*n style="font-family:宋体">使用方法

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">1<*n style="font-family:宋体">、检查环境温度

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">施工期间,施工地点的气温须控制在<*n style="font-size:10.5000pt"><*n style="font-family:Calibri">5<*n style="font-size:10.5000pt"><*n style="font-family:宋体">℃至<*n style="font-size:10.5000pt"><*n style="font-family:Calibri">40<*n style="font-size:10.5000pt"><*n style="font-family:宋体">℃之间,如气温过低时,材料本身及施工区域则须加温至<*n style="font-size:10.5000pt"><*n style="font-family:Calibri">5<*n style="font-size:10.5000pt"><*n style="font-family:宋体">℃以上,直到*陶瓷施工完毕为止。应避免在直接日晒或强风状况下施工,防止管道热胀冷缩造成的陶瓷片互相挤压而影响粘接强度,强风下禁止施工,因风造成的扬尘会严重影响陶瓷胶的粘结强度。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">2<*n style="font-family:宋体">、对要采取防磨的部位搭设脚手架,脚手架要求施工人员便于粘接施工及打磨。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">3<*n style="font-family:宋体">、进行表面处理,用清扫工具将施工部位的浮灰、杂物等清扫干净。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">4<*n style="font-family:宋体">、机械除锈,用喷砂机或角向打磨机除垢、除锈、除杂物,直至露出金属光泽。作到表面光滑平整。有严重磨损部位,需要补焊或者更换设备后再仔细打磨。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">5<*n style="font-family:宋体">、清洗,用或者无水酒精除锈以达到表面清洗干净。洗净施工表面污染物和油污。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">6<*n style="font-family:宋体">、刮胶泥,将瓷胶和固化剂按比例调配,取<*n style="font-family:Calibri">4<*n style="font-family:宋体">份胶、<*n style="font-family:Calibri">1<*n style="font-family:宋体">份固化剂,便于施工可以取<*n style="font-family:Calibri">200<*n style="font-family:宋体">克胶<*n style="font-family:Calibri">50<*n style="font-family:宋体">克固化剂,放在一个便于和胶的托盘上,然后搅匀,一定要搅匀,然后把胶刮涂在施工陶瓷板上(陶瓷板上的焊接孔为沉头孔,缩孔部位的表面涂抹胶水,但不要把胶水涂抹在孔的边缘,因为把陶瓷板压实的话,胶水会挤入到孔内造成无法焊接的困难),粘接剂涂抹均匀,不得有漏涂现象,也不要涂抹厚度超过<*n style="font-family:Calibri">1mm<*n style="font-family:宋体">,然后把陶瓷板按照顺序粘接到金属筒壁上。(严格按照工艺比例混胶,并保证混合均匀;每次混胶量以随用随配为原则),注意:陶瓷片在刮胶前要检查表面毛刺,并清理表面污物。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">7<*n style="font-family:宋体">、粘贴

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">将刮好胶的陶瓷板按顺序贴在施工部位,用橡皮锤轻轻敲实。陶瓷板装贴需紧密贴紧筒壁,陶瓷装贴应平整并应尽可能形成光滑面,每相邻的陶瓷块的高低差应小于<*n style="font-size:10.5000pt"><*n style="font-family:Calibri">0.<*n style="font-size:10.5000pt"><*n style="font-family:宋体">1<*n style="font-size:10.5000pt"><*n style="font-family:Calibri">mm<*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">8<*n style="font-family:宋体">、陶瓷粘贴后,待胶水固化<*n style="font-family:Calibri">24<*n style="font-family:宋体">小时后,(如果需要焊接)即可进行焊接作业

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">9<*n style="font-family:宋体">、所有的陶瓷黏贴后,可对*陶瓷进行焊接,首先把焊接铁碗(锥形的铁圈)涂抹一点胶水,然后放入到孔内并推入到孔的底部。切记不要把铁碗的中心孔涂抹胶水。安排的焊接工人对铁碗进行焊接,保证铁碗和钢板能够焊接牢固即可。可以采用二保焊也可以采用焊条直接点焊。注意:铁碗电焊牢固即可,切不可填充焊接,过多的焊接会造成陶瓷的炸裂。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">10<*n style="font-family:宋体">、铁碗焊接完成后,使用*的陶瓷柱对焊接孔进行封堵,在陶瓷柱的侧面涂抹胶水,然后塞到孔内即可。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">11<*n style="font-family:宋体">、由于管道、旋风筒、溜槽、落料管等尺寸不匹配,不能使用陶瓷板全部覆盖到位,因此需要对陶瓷之间的夹角、间隙、以及陶瓷接头等部位进行填充,可以把剩余的陶瓷板砸成细小的颗粒或者由供货厂家提供刚玉砂混合陶瓷胶制成*胶泥进行填缝。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">12<*n style="font-family:宋体">、所有需要粘接陶瓷板的地方粘接到位、所有的焊接孔焊接完毕以及对孔进行封闭作业完成、所有的陶瓷间隙进行填充即可验收并投入使用。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">13<*n style="font-family:宋体">、自检、修整

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体"><*n style="font-family:宋体">粘贴完成后进行检查,陶瓷衬片外表面光滑平整,无深度滑痕及*裂现象,确保粘贴后平整,发现不合格处进行修整。

<*n style="font-size:10.5pt"><*n style="font-family:Calibri"><*n style="font-size:10.5000pt"><*n style="font-family:宋体">14<*n style="font-family:宋体">、注意事项,粘贴好后需自然固化<*n style="font-family:Calibri">24<*n style="font-family:宋体">小时后方可投入使用。