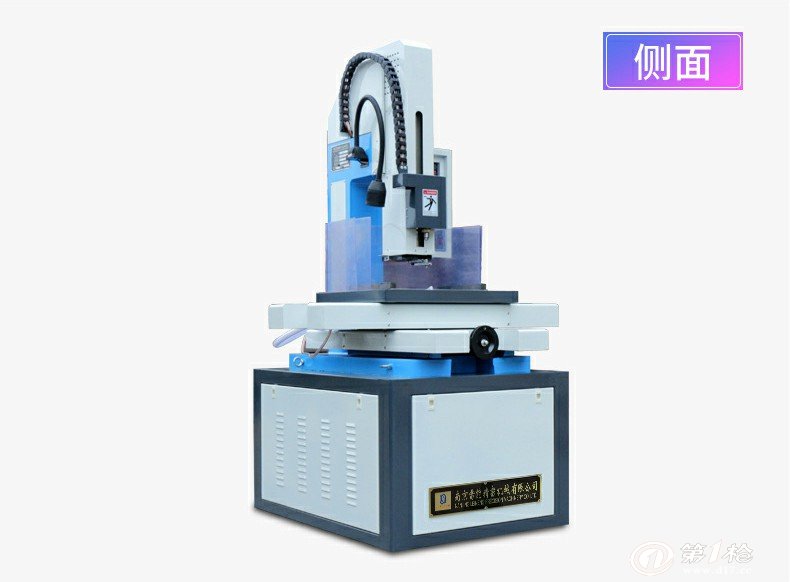

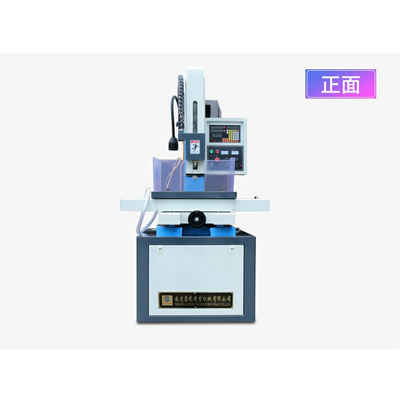

南京电火花穿孔机 电火花小孔机 D703

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:16.0pt"><*n style="font-family:方正兰亭中黑_GBK">南京雷能穿孔机性能参数

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆">产品说明: 主要用途和适用范围:

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 本机床操作简单方便,主轴采用直流伺服或步进电机驱动,转速可调,加工稳定性好,噪音低。工作台移动光栅数显,可以根据电ji-工件和电ji材料的不同选择加工参数,参数调节范围大。可以直接从工件曲面、斜面穿入。工件液可直接使用自来水,用纯净水(蒸馏水、去离子水)加工效果更佳。

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 本机床主要用于加工不锈钢、淬火钢、硬质合金、铜、铝等各种导电材料上深径比大的小孔。深径比可达200:1。

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 本机床也能用于蚀除折断在工件中的钻头、丝锥而不损坏原孔或螺纹。

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆">小孔机(Small hole EDM machine)

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 电火花高速小孔机属于电火花加工(Electro Spark Erosion)又称放电加工(Electro Discharge Machining)机床的一种。

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 别名:小孔机、打孔机、穿孔机

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 和快走丝、中走丝、慢走丝、电火花成型机和电火花内孔、外圆磨床一样都是电火花加工机床。

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"> 工作原理:利用连续移动的细金属丝(称为电ji丝)作电ji,对工件进行脉冲火花放电蚀除金属、切割成型。与电火花线切割机床、成型机不同的是,它电脉冲的电ji是空心铜棒。介质从铜棒孔穿过与工件发生放电,腐蚀金属达到穿孔的目的,用于加工超硬钢材、硬质合金、铜、铝及任何可导电性物质的细孔。

<*n style="font-size:10.5pt"><*n style="background-color:white"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:幼圆"><*n style="color:black">性能特点:

1.能加工直径Φ0.3-3.0mm的深小孔(深径比可达200:1)。

2.加工速度可达每分钟30-60mm(视材料而定)。

3.能加工线切割起始孔、过滤孔、喷嘴孔、气孔、群孔、超深孔等。

4.能加工不同的导电材料,甚至是半导体材料,特别适用与加工不锈钢、淬火钢、钢、铜、铝、硬质合金等。

5.可直接在工件斜面、曲面上加工。

6.可蚀除折断在工件中的鑽头、丝锥等,而不损坏原孔螺纹。

7.工作液可直接采用纯水(自来水),也可使用皂化液,*。

8.工作台XY两轴配有数显装置。

9.操作简单,方便。具有穿孔*,加工精度*可靠,质量稳定等优点。

<*n style="font-size:10.5pt"><*n style="background-color:white"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:14.0pt"><*n style="font-family:宋体"><*n style="color:black">技术参数:

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">机床型号 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">LN-DD703 |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">工作台尺寸 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">320×400mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">工作台行程 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">300×400mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">电ji直径 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">Φ0.3-Φ3mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">主轴伺服行程 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">380mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">主轴二次行程 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">350mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">导向器与工作台面的距离 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">370 |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">工作台面高度 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">920 |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">输入功率 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">3kw |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">加工电流 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">30A |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">加工速度 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">30-60mm/min |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">主机外型尺寸 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">850×1100×2000mm |

|

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:宋体"><*n style="color:black">主机重量 |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:9.5pt"><*n style="font-family:"Arial",sans-serif"><*n style="color:black">800kg |

<*n style="font-size:10.5pt"><*n style="font-family:"Times New Roman",serif"><*n style="font-size:15.0pt"><*n style="font-family:黑体"><*n style="color:red">选配:①打孔定深控制电气 ②LN-DD703L(XY轴直线导轨)