供应超细超微粉碎蒸汽双喷扁平气流粉碎机

超细超微粉碎机,蒸汽双喷扁平气流粉碎机<*n>

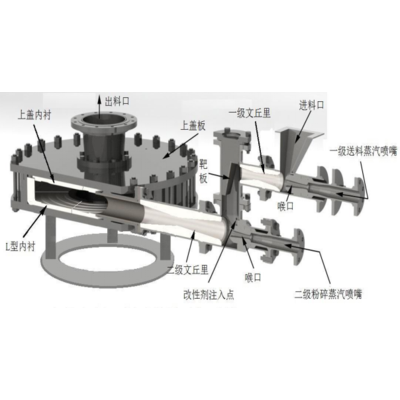

ZJ<*n>超细超微粉碎机蒸气双喷扁平气流粉碎机是我公司根据钛bai粉的粉碎要求,即粒度分布窄、夹杂增加少、分散性好;以及钛bai粉物料粘度高、流动性差、粒度细且容易附壁等特性,开发出的钛bai粉****终粉磨*汽流粉碎机。 <*n>

目前国内外钛bai生产厂家均选用具有自分级功能的扁平式(亦称水平圆盘式)气流粉碎机作为钛bai粉的****终粉碎设备;并且使用过热蒸汽为粉碎工质,在高温状况下粉碎,可****钛bai粉的应用分散性,增加钛bai粉的流动性。能耗低,仅为压缩空气的<*n> 1/3~<*n>2/3。 <*n>

使用<*n>ZJ蒸气双喷扁平气流粉碎机,可在粉碎的同时,加入有机助剂,对钛bai粉进行表面有机改性,以增加钛bai粉在不同应用体系中的分散性。 作为气流粉碎的****重要设备,气流粉碎机的好坏直接决定产品的质量。故要求气流粉碎机设计合理、制作精良、冲击动能大、分级效果好、*磨损、耐高温。 <*n>

设备特点<*n>: 与传统的扁平式气流粉碎机相比,有了很大的改进及****,该机充分利用了过热蒸汽的全部能量,物料在同一台设备内,经过两次粉碎分级,使产品的粒度更细,粒度分布更窄,质量更好。 <*n>

1、<*n> 内衬采用超硬*材料的特殊镶嵌结构大大****了气流粉碎机的使用寿命及粉碎效果。 <*n>

2、<*n> 产品细度高:<*n>d90=0.3~10μ<*n>m,粒度分布窄且无大颗粒。 <*n>

3、<*n> 粉磨*,能耗低,比其它类型气流磨节能<*n> 30%; <*n>

4、<*n> 采用<*n> Al2O3、<*n>SiC或<*n> Pu(钚)作易磨损件,磨耗低,产品受污染少,可加工无铁质污染的粉体产品和莫氏<*n> 9 级的物料,特别适用于氯化法钛bai粉的生产; <*n>

5、<*n> 结构紧凑、噪音小、成本相对较低。 <*n>

6、<*n> ZJ蒸气双喷扁平汽流粉碎机采用导管自动分级,使用过热蒸汽为粉碎工质时,很容易实现。 <*n>

7、<*n> 粉碎腔内衬采用超**冲击*材料,运用特殊镶嵌可缓冲结构,有效克服了*材料易碎裂的问题,使其使用寿命得到保障。 <*n>

工艺流程<*n>Technological process

应用领域<*n>&nb*pplication area

钛bai粉的****终粉碎<*n>The final grinding of titaniu*oxide

主要技术参数<*n> Main Parameters

|

<*n style="font-size:12.0pt;font-family:宋体;color:white;">设备型号<*n> <*n style="font-size:12.0pt;font-family:宋体;color:#333333;"> <*n style="font-size:12.0pt;font-family:宋体;color:white;">Model<*n style="font-size:12.0pt;font-family:宋体;color:#333333;"> |

<*n style="font-size:10.0pt;font-family:"color:white;">介质温度 <*n> <*n style="font-size:10.0pt;font-family:"color:white;">Medium temperature |

<*n style="font-size:10.0pt;font-family:"color:white;">料气比 <*n> <*n style="font-size:10.0pt;font-family:"color:white;">Gas solid ratio |

<*n style="font-size:10.0pt;font-family:"color:white;">成品细度<*n style="font-size:10.0pt;font-family:"color:#333333;"> <*n> <*n style="font-size:10.0pt;font-family:"color:white;">Product Size<*n style="font-size:10.0pt;font-family:"color:#333333;"> |

<*n style="font-size:10.0pt;font-family:"color:white;">生产能力<*n style="font-size:10.0pt;font-family:"color:#333333;"> <*n> <*n style="font-size:10.0pt;font-family:"color:white;">Capacity<*n style="font-size:10.0pt;font-family:"color:#333333;"> |

<*n style="font-size:10.0pt;font-family:"color:white;">介质压力 <*n> <*n style="font-size:10.0pt;font-family:"color:white;">Medium pressure |

|

<*n style="font-size:10.0pt;font-family:"color:#333333;">ZJ300 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">280-3100C |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.3-1.5:1 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">0.3-10µm |

<*n style="font-size:10.0pt;font-family:"color:#333333;">10-50kg/h |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.6-2.5MPa |

|

<*n style="font-size:10.0pt;font-family:"color:#333333;">ZJ800 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">280-3100C |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.3-1.5:1 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">0.3-10µm |

<*n style="font-size:10.0pt;font-family:"color:#333333;">200-400kg/h |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.6-2.5MPa |

|

<*n style="font-size:10.0pt;font-family:"color:#333333;">ZJ1000 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">280-3100C |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.3-1.5:1 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">0.3-10µm |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.5-2t/h |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.6-2.5MPa |

|

<*n style="font-size:10.0pt;font-family:"color:#333333;">ZJ1100 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">280-3100C |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.3-1.5:1 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">0.3-10µm |

<*n style="font-size:10.0pt;font-family:"color:#333333;">2-3t/h |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.6-2.5MPa |

|

<*n style="font-size:10.0pt;font-family:"color:#333333;">ZJ1200 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">280-3100C |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.3-1.5:1 |

<*n style="font-size:10.0pt;font-family:"color:#333333;">0.3-10µm |

<*n style="font-size:10.0pt;font-family:"color:#333333;">3-4t/h |

<*n style="font-size:10.0pt;font-family:"color:#333333;">1.6-2.5MPa |

ZJ double flat steam jet mill is our

company according to the requirements of grinding of titaniu*oxide, namely

narrow particle size distribution, inclusion and less increase of dispersion;

and titaniu*oxide material with high viscosity and poor fluidity, fine

granularity and easy adhesion characteristics, developed the final grinding

titaniu*oxide special steam mill.

At present, domestic and foreign manufacturers h*e also chosen

titaniu*oxide with flat type self classification function (also known as

horizontal disc type) jet mill as the final crushing equipme*f titaniu*oxide; and used as grinding age*f superheated steam, crushing under high

temperature conditi*, can improve the application of titaniu*oxide

dispersion, increase the liquidity of titaniu*oxide. The energy c*umption is

low, only 1/3 to 2/3 of compressed air.

The use of ZJ double flat steam jet mill, the material at the

same time, the addition of organic additives to the titaniu*oxide surface

organic modificatio*increase the dispersion of titaniu*oxide in different

application in the system. As the most important equipment for airflow

grinding, the quality of the product is directly determined by the airflow

mill. Therefore, the design of the air crusher is reasonable, the manufacture

is excellent, the impact energy is large, the classification effect is good,

and the wear resistance and heat resistance are high.

Equipment features:

Compared with the traditional flat jet mill, and h*e great improvements, thi*achine can make full use of all the energy of superheated steam, the material

in the same equipment, after two times of grinding classification, make the

product more fine granularity, narrow size distribution, better quality.

1, the lining adopts the special mosaic structure of superha*ear-resistant

material, which greatly improves the service life of the air pulverizer and the

grinding effect.

2, the product fineness is hig*0.3~10 m, the size distribution is narrow

and no big particles.

3, high grinding efficiency, low energy c*umption, energy s*ing than other

types of airflow mill 30%;

4, using Al2O3, SiC or Pu (plutonium) are easy to wear, low abrasion, les*ontamination of the product, can be processed without iron pollution of powder

products and 9 Mohs grade material, especially suitable for the chlorination

process titaniu*oxide production;

5, compact structure, low noise, relatively low cost.

6, ZJ double flat steam steam pulverizer adopts automatic gr*g tube, using

superheated steam for crushing the working fluid, easy to implement.

7,The lining of the c*ity i*ade of super abrasion resistance, impact resistance and abrasion resistant materials. The special mosaic and buffering structure can effectively overcome the problem of brittle fracture of wear-resistant materials, and ensure the service life of the wear-resistant materials.

<*n>