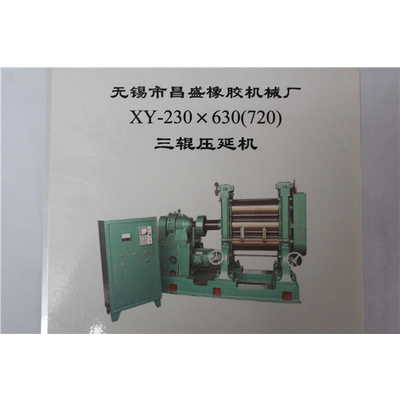

无锡市昌盛橡胶机械厂(图),三辊压延机订购,徐州三辊压延机

First, Application and classification

1. Application

The calender i*ainly used for the ru*er pressing,徐州三辊压延机, the cover ru*er of the textile, the cover ru*er of the steel cord, the ru*er embryo pressure type, the sheet fitting, the impurities in the compound and the isolation film.

2. Classification

(1) According to usage,三辊压延机购买, the calendering machine can be classified i* compression table press, gluing calender, compression crimping machine, laminating calender, pressure calender, calendering calender and lab calender. (2) According to number of roller, classification can be divided i* two roller calendar, three-roll calender, four-roll calender and five-roll calender.

(3) According to the arrangeme*f roller, can be divided i* I-type rolling machine,三辊压延机参数, △ -type calender, L-shaped calender, Z-calender, S-calender.

(一)工作原理

1,相对回转---两个相邻的辊筒在有速比或等速情况下相对回转;

2,胶料在摩擦力作用下被拉入辊隙中,

3,由于辊隙截面的逐渐减少,三辊压延机订购,使胶料受到强烈的挤压与剪切,完成延展成型(压片);或把胶料挤压在钢丝帘布上(双面贴胶);胶胚表面压花(压型);多层胶片的贴合等.由于辊隙截面的逐渐减少,使胶料受到强烈的挤压与剪切,完成延展成型(压片);或把胶料挤压在钢丝帘布上(双面贴胶);胶胚表面压花(压型);多层胶片的贴合等.

化学工业上什么是辊速比相关论述

辊速比

英文名称: roll speed ratio;friction ratio CAS号: 分 子 式:

相关内容概述: 指相邻两个辊筒线速度之比,是压延机操作中使用的术语。压延机在加工塑料薄膜或片材的时候,利用相邻压延辊线速度的不同和辊距的变化等,使塑料在压延1时能更好地进行剪切、塑化,使料片顺利地从一个压辊转移到另一压辊上,从而获得规定厚度和满意质量的成品,压延机就是根据辊筒配置情况,分别称L型三辊压延机、Z型四辊压延机等。开炼机的辊速比一般为1:1.2~1:1.3。压延机擦胶时的三辊筒的速比一般为1:1.3~1.5:1(上辊:中辊:下辊)。辊筒速比的大小表示两辊间的剪切力与摩擦力的大小。密炼机的辊筒转速较快,故速比较低,一般为1:1.14~1:1.19

无锡市昌盛橡胶机械厂(图),三辊压延机订购,徐州三辊压延机由无锡市昌盛橡胶机械厂提供。无锡市昌盛橡胶机械厂(图),三辊压延机订购,徐州三辊压延机是无锡市昌盛橡胶机械厂(www.wxcsxj*)今年全新升级推出的,以上图片仅供参考,请您拨打本页面或图片上的联系电话,索取联系人:徐经理。