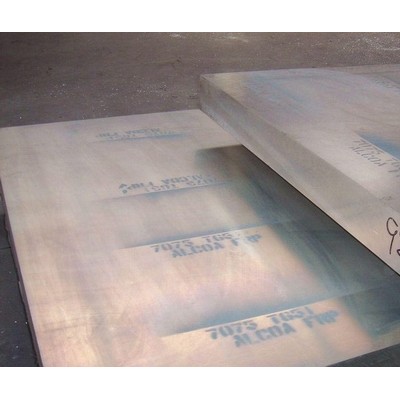

6082铝板价格,6082铝板厂家,6082铝板规格

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">6082<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">属于<*n lang="EN-US">6×××<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">系列(<*n lang="EN-US">Al-Mg-Si<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">)合金铝板,是能够热处理可强化的铝合金板材,具有中等强度和良好的焊接性能、耐腐蚀性,主要用于交通运输和结构工程工业。如桥梁、起重机、屋顶构架、运输机、运输船等。近年来,随着国内外造船业突飞猛进的发展,减轻船体自重,****船速,寻求代替钢铁部件的铝合金材料,已成为铝加工业和造船业面临的重要课题。<*n lang="EN-US">6082<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">铝合金铝板具有中等强度和良好的耐蚀性,重量又轻,是制造高速船部件的理想材料。<*n lang="EN-US">

<*n lang="EN-US">6082<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">铝合金的化学成分

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 硅<*n lang="EN-US">Si<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.7<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">~<*n lang="EN-US">-.3<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">;

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">铁<*n lang="EN-US">Fe<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">5.0<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 铜<*n lang="EN-US">Cu<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.10<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 锰<*n lang="EN-US">Mn<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.4<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">~<*n lang="EN-US">1.0<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 镁<*n lang="EN-US">Mg<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.6<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">~<*n lang="EN-US">1.2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 铬<*n lang="EN-US">Cr<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.25<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 锌<*n lang="EN-US">Zn:0.20<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 钛<*n lang="EN-US">Ti<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.10<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">;<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 铝<*n lang="EN-US">AL<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:余量。<*n lang="EN-US">

<*n lang="EN-US">6082<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">铝合金的力学性能

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> *拉强度<*n lang="EN-US">σb (MPa)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">≥205

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 条件屈服强度<*n lang="EN-US">σ0.2 (MPa)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">≥110

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 伸长率<*n lang="EN-US">δ10 (%)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">≥14

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 注 <*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">:型材室温纵向力学性能<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 试样尺寸:所有厚度<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 均匀化温度:<*n lang="EN-US">555-565<*n style="font-family:宋体;mso-bidi-font-family:宋体">℃<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">保温时间:<*n lang="EN-US">3<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">小时,冷却速度<*n lang="EN-US">≥200<*n style="font-family:宋体;mso-bidi-font-family:宋体">℃<*n lang="EN-US">/

<*n lang="EN-US">6082<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">铝合金的热处理工艺

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">1<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、熔炼<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">6082<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">合金特点是含<*n lang="EN-US">Mn<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">,<*n lang="EN-US">Mn<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">是难熔金属,熔炼温度应控制在<*n lang="EN-US">740-760<*n style="font-family:宋体;mso-bidi-font-family:宋体">℃<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">。取样前均匀搅拌两次以上,保证金属完全熔化、温度准确、成分均匀。搅拌后在铝液深度的中部、炉膛左右两侧各取一个样进行分析,分折合格后即可转炉。<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、净化与铸造<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 熔体转入静置炉后,用氮气和精炼剂进行喷粉、喷气精炼,精炼温度<*n lang="EN-US">735-745<*n style="font-family:宋体;mso-bidi-font-family:宋体">℃<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">,时间<*n lang="EN-US">15<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">分钟,精炼完后静置<*n lang="EN-US">30<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">分钟。通过此过程除气、除渣、净化熔体。<*n lang="EN-US">

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 熔铸时在铸模至炉口间有两道过滤装置,炉口有泡沫陶瓷过滤板<*n lang="EN-US">(30PPI)<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">过滤,铸造前用<*n lang="EN-US">14<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">目玻璃纤维丝布过滤,充分滤去熔体中的氧化物、夹渣。<*n lang="EN-US">

<*n lang="EN-US">6082<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">合金铝板铸造温度偏高<*n lang="EN-US">(<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">较<*n lang="EN-US">6063<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">铝板正常工艺<*n lang="EN-US">)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">,铸造速度偏低,水流量偏大,上述工艺需严格控制,不能超出范围,否则容易导致铸造失败。