山东304不锈钢自动圆型厨具桶自动直缝焊接机器设备

产品属性

- 焊机:

- 氩弧焊 二保焊 等离子焊

- 电源:

- 220/380

- 焊接类型:

- 不锈钢 镀锌 碳钢 钛金板 铁

- 品牌:

- 其他

- 类型:

- 其他

- 电源类型:

- 直流

- 额定电流等级:

- 315

- 控制方式:

- 自动

- 工作周期:

- 连续

- 是否数控:

- 否

- 电源控制方法:

- 其他

- 送丝系统:

- 行星式

- 冷却方式:

- 水冷

- 绝缘等级:

- A

- 型号:

- ZF-1000

- 额定负载持续率:

- 1000

- 焊接电流范围:

- 350

- 焊接材质:

- 不锈钢201 304 403

- 适用板厚:

- 0.5-2.5

- 额定输入电压:

- 380V

- 额定输入容量:

- 200

- 空载电压:

- 380

- 效率:

- 连续

- 功率因数(COSφ):

- 要求

- 适用焊丝直径:

- 0.8-1.0-1.2-1.6

- 保护气体类型:

- 氩气

- 作用原理:

- 直缝焊

- 电压调节范围:

- 1-

- 外形尺寸:

- 可定制

- 重量:

- 550

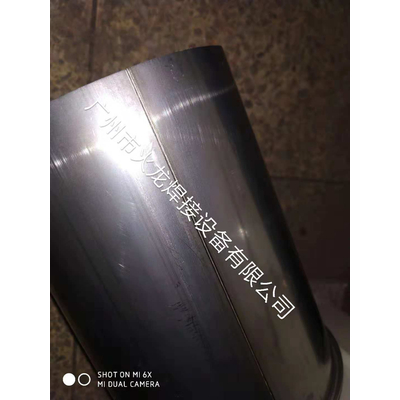

全自动*弧直缝焊接机质量的机械工艺奠定了焊接的质量,不变形、无压痕、直线性。可选用PLC自动控制或继电器集成控制。铜合金压紧机构保证了工件的不变形

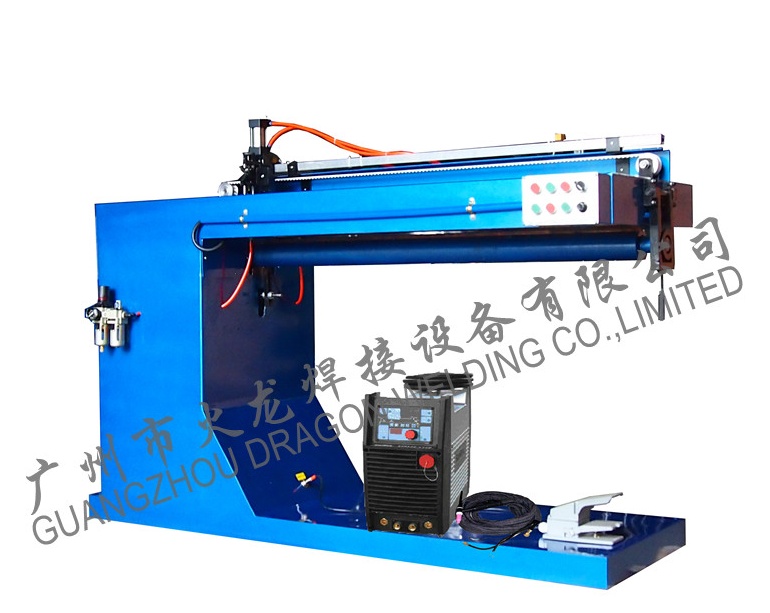

ZF系列自动*弧(等离子)直缝焊机

ZF Series Automatic Argon Arc (Pla*a) Longitudinal Seam Welding Machine

整机特性:

1. 自动直缝焊机主要用于不锈钢、铝、黄铜等各种金属的圆筒、拼板的质量、低变形的直线性自动焊接;

2. 本机采用琴键式铜合金压紧机构,提供均匀稳定的工件夹持和冷却效果;

3. 配备焊缝背面保护衬套和成型槽,以保证提供稳定的气体保护和确保达到单面焊接双面成型的效果;

4. 本机可按要求选用PLC或继电器集成控制;

5. 焊行走采用直流电机驱动,焊接速度无****可调;

6. 可任意匹配各种类型弧焊电源(*弧焊/CO2焊/等离子弧焊)。

1、焊接主机采用悬臂结构,机架由钢材料折弯焊接而成;

2、 气动琴键式压紧结构,沿直缝两侧紧密排列,保证对接焊缝在整个焊接长度范围内均匀压紧;左右琴键压指的间距可调整,以适应不同工件的焊接;

3、根据工件的厚度尺寸可采用气囊式或气缸式,保证有足够的压紧力,****焊接过程中的热变形;

4、 焊接芯轴镶嵌有铜制胎具,提供焊缝背气保护功能;根据筒体或平板工件加工不同焊接工艺槽,达到单面焊双面成型;

5、 焊接芯轴与琴键压指间距可调,可适应不同工件焊接要求;

6、焊行走采用直流伺服电机驱动,齿轮齿条传动,轨道面经磨削加工,行走平稳,焊接稳定可靠。

7、所有气管、电缆安放在拖链内,外观整洁美观,同时避免线缆断线。

|

<*n style="font-family:宋体;font-size:8pt;">型号<*n style="font-family:"font-size:8pt;"> <*n style="font-family:宋体;font-size:8pt;">Model<*n style="font-family:宋体;font-size:8pt;"> <*n style="font-family:宋体;font-size:8pt;">项目Item<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-300<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;"> ZF<*n style="font-family:"font-size:8pt;">-500<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-800<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-1000<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-1200<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-1500<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">ZF<*n style="font-family:"font-size:8pt;">-2000<*n style="font-family:"font-size:8pt;"> |

|

<*n style="font-family:宋体;font-size:8pt;">输入电压<*n style="font-family:"font-size:8pt;"> Input voltage<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">Single Phase <*n style="font-family:"font-size:8pt;">220V, 50/60Hz<*n style="font-family:"font-size:8pt;"> |

||||||

|

<*n style="font-family:宋体;font-size:8pt;">焊接长度<*n style="font-family:"font-size:8pt;">(mm) Max welding length<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">3<*n style="font-family:宋体;font-size:8pt;">0<*n style="font-family:"font-size:8pt;">0mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">500mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">1000mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">1200mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">1500mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">2000mm<*n style="font-family:"font-size:8pt;"> |

|

<*n style="font-family:宋体;font-size:8pt;">工件直径<*n style="font-family:"font-size:8pt;"> (mm) Workpiece diameter<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">50<*n style="font-family:"font-size:8pt;">-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">7<*n style="font-family:"font-size:8pt;">0-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">90<*n style="font-family:"font-size:8pt;">-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">100<*n style="font-family:"font-size:8pt;">-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:宋体;font-size:8pt;">100<*n style="font-family:"font-size:8pt;">-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">1<*n style="font-family:宋体;font-size:8pt;">20<*n style="font-family:"font-size:8pt;">-800mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">1<*n style="font-family:宋体;font-size:8pt;">8<*n style="font-family:"font-size:8pt;">0-<*n style="font-family:宋体;font-size:8pt;">80<*n style="font-family:"font-size:8pt;">0mm<*n style="font-family:"font-size:8pt;"> |

|

<*n style="font-family:宋体;font-size:8pt;">适用厚度<*n style="font-family:"font-size:8pt;"> Workpiece thickness<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">0.3-3mm<*n style="font-family:"font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">0.4-3mm<*n style="font-family:"font-size:8pt;"> |

|||||

|

<*n style="font-family:宋体;font-size:8pt;">焊接速度<*n style="font-family:"font-size:8pt;"> Welding Speed<*n style="font-family:宋体;font-size:8pt;"> |

<*n style="font-family:"font-size:8pt;">300-2000mm/min<*n style="font-family:"font-size:8pt;">

<*n style="font-family:"font-size:8pt;">

|