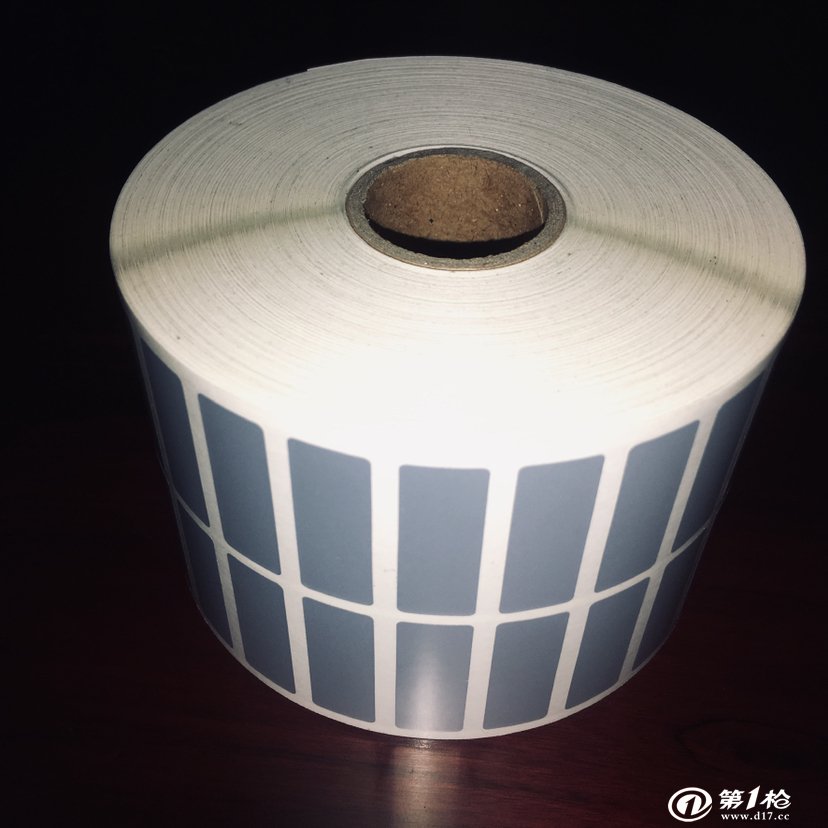

苏州昆山3M7871防油PET无尘标签95x95MMx1K

产品属性

- 12:

- 12

- 品牌:

- 其他

- 类型:

- 不干胶贴标机

- 运动方式:

- 直线式贴标机

- 自动化程度:

- 全自动

- 型号:

- 3M7872

3M-7872Thermal Transfer PolyesterLabel Material

Features • Facestock is topcoated for thermal transfer printing. Resin ri** are

recommended for optimum durability. The topcoat also provides improved ink

anchorage for traditional forms of press printing.

• #350 adhesive is 3M&rsquo*ost universal adhesive for label materials. It can

permanently bond to high surface energy (HSE) and low surface energy (LSE)

plastics, textured and co*ured surfaces, powder coatings, and slightly oily

metals. It has excellent chemical resistance and holding strength even at high

temperatures. Thick adhesive caliper provides for stronger bond on textured

surface.

• 55# densified kraft liner assures c*isten*e cutting.

• 3M™ Label Material 7872 is UL recognized (File MH16411) and CSA accepted

(File 99316). See the UL and CSA listings for details.

• UL listing includes approval for use on powder coated surfaces.

Technical Data April 15, 1999

Application Ideas • Barcode labels and rating plates.

• Property identification and asset labeling.

• Warning, instruction, and service labels for durable goods.

• Nameplates for durable goods.

• Substitutes for stamped metal, riveted plates.

C*truction

FOD# 1416

page 1 of 5

Supersede*arch 9,1998

Note: The following technical information and data should be c*idered

representative or typical only and should not be used for specification pur*es.

Adhesion: 180° peel test procedure is ASTM D 3330.

90° peel test procedure is ASTM D 3330 modified for the angle change.

Initial Conditioned for 3 Days at Room

(10 Minute Dwell/RT) Temperature 72°F (22°C)

180° Peel 90° Peel 180° Peel 90° Peel

Surface Oz./In. N/100 mm Oz./In. N/100 mm Oz./In. N/100 mm Oz./In. N/100 mm

Stainless Steel 88 96 63 69 96 105 75 82

Polycarbonate 90 98 65 71 94 103 69 76

Polypropylene 73 80 29 32 83 91 31 34

Glass 93 102 69 76 99 108 77 84

LD Polyethylene 54 59 27 30 58 63 32 35

HD Polyethylene 53 58 30 32 56 61 37 40

Smooth

Powder Coating 85 93 89 97

Finely Textured

Powder Coating 49 54 52 57

Conditioned for 3 Days at Conditioned for 24 hours at 90°F

120°F (49°C) (32°C) at 90% Relative Humidity

180° Peel 90° Peel 180° Peel 90° Peel

Surface Oz./In. N/100 mm Oz./In. N/100 mm Oz./In. N/100 mm Oz./In. N/100 mm

Stainless Steel 108 118 96 105 99 108 81 89

Polycarbonate 66 72 34 37 77 84 59 64

Polypropylene 81 89 33 16 78 85 47 51

Glass 106 116 86 94 89 97 72 79

LD Polyethylene 56 61 32 35 50 55 38 42

HD Polyethylene 15 16 14 15 43 47 40 44

Smooth

Powder Coating 93 102 88 96

F inely Textured

Powder Coating 56 61 50 55

Liner Release: 180° Removal of Liner from Facestock

Rate of Removal Grams/Inch Width N/100 mm

90 inche*inute 16 0.62

300 inche*inute 22 0.85

3M™ Thermal Transfer Polyester Label Material

7872

Typical Physical

Properties

FOD# 1416

page 2 of