河南棕刚玉厂家 棕刚玉耐火材料 喷砂棕刚玉 研磨抛光棕刚玉

产品属性

- 外观:

- 棕色颗粒

- 冶炼:

- 电熔

- 厂家:

- 是,1999年建厂

- 莫氏硬度:

- 9

- 关键词:

- 棕刚玉

- 品牌:

- 海旭

- 类型:

- 棕刚玉

- 型号:

- 棕刚玉

- 粒度:

- 棕刚玉

- 规格重量:

- 棕刚玉,25千克

棕刚玉F24目:

棕刚玉F30目:

棕刚玉F36目:

用途:

|

河南棕刚玉厂家 棕刚玉耐火材料 喷砂棕刚玉 研磨抛光棕刚玉 1.棕刚玉理化指标:

棕刚玉段砂:

|

一、棕刚玉简介

棕刚玉是以铝矾土、*煤为主要原料,在2000度以上电弧炉内经高温冶炼而成,用它制成的磨具,适于磨削张较高(钢材、可锻铸铁、应青铜等)的金属,适用于制造陶瓷、树脂高固结磨具以及研磨、抛光、喷砂、铸造等,也可制造耐火材料。棕刚玉具有纯度高,结晶好,流动性强,线膨胀系数低,耐腐蚀、耐高温、高强度等特点。

Brown fused alumina i*ade of bauxite, anthracite coal, and *elted in electric-arc furnace of high temperature more than 2000 degrees. Abrasives tool*ade by brown fused alumina are suitable for metal with high tensile(like: steel, malleable iron, bronze etc). Suitable for product high c*olidation abrasive, and suitable for grinding, polishin*asting, precision casting etc. brown fused alumina is also used for refractory material. Brown fused alumina with characteristics like: high purity, good crystalline liquidity, low coefficie*f linear expansion, corrosion resistance, high temperature, high strength.

二、棕刚玉所有可供型号:

|

产品 |

型号 |

|

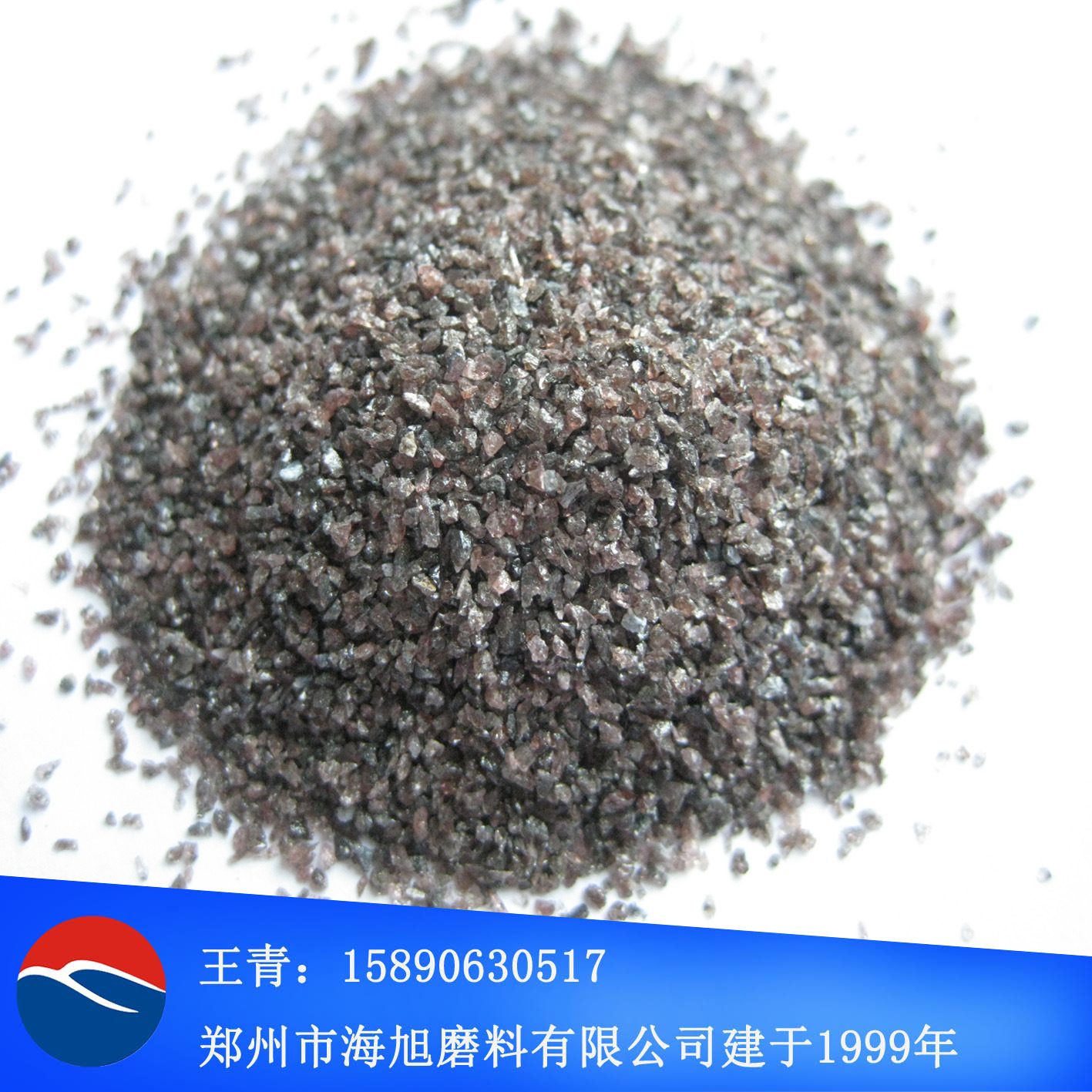

段砂 |

8-5mm,5-3mm,3-1mm,1-0mm |

|

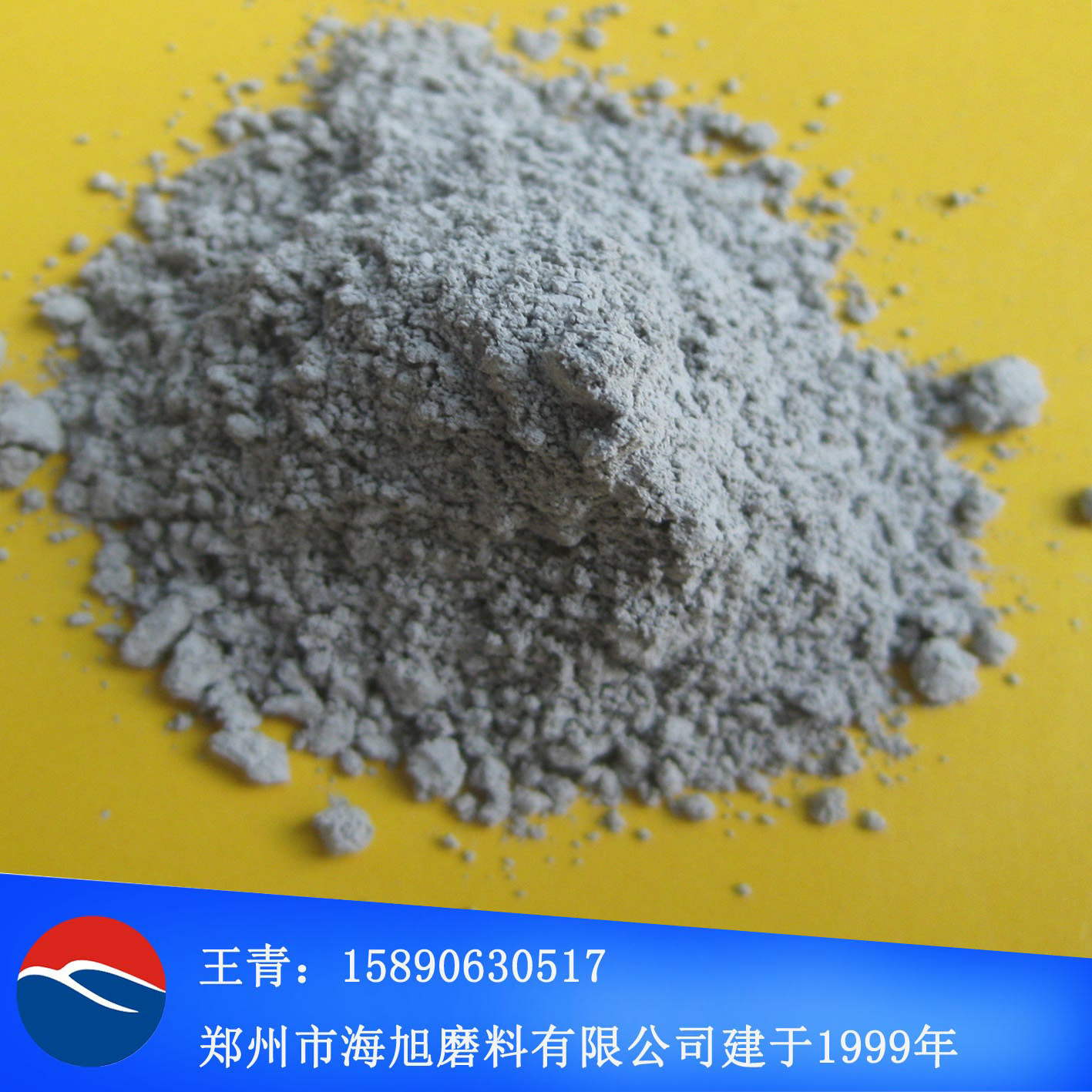

细粉 |

320-0,200-0,180-0,150-0,120-0,100-0,320F, 280F, 240F, 200F, 180F, 150F, 100F |

|

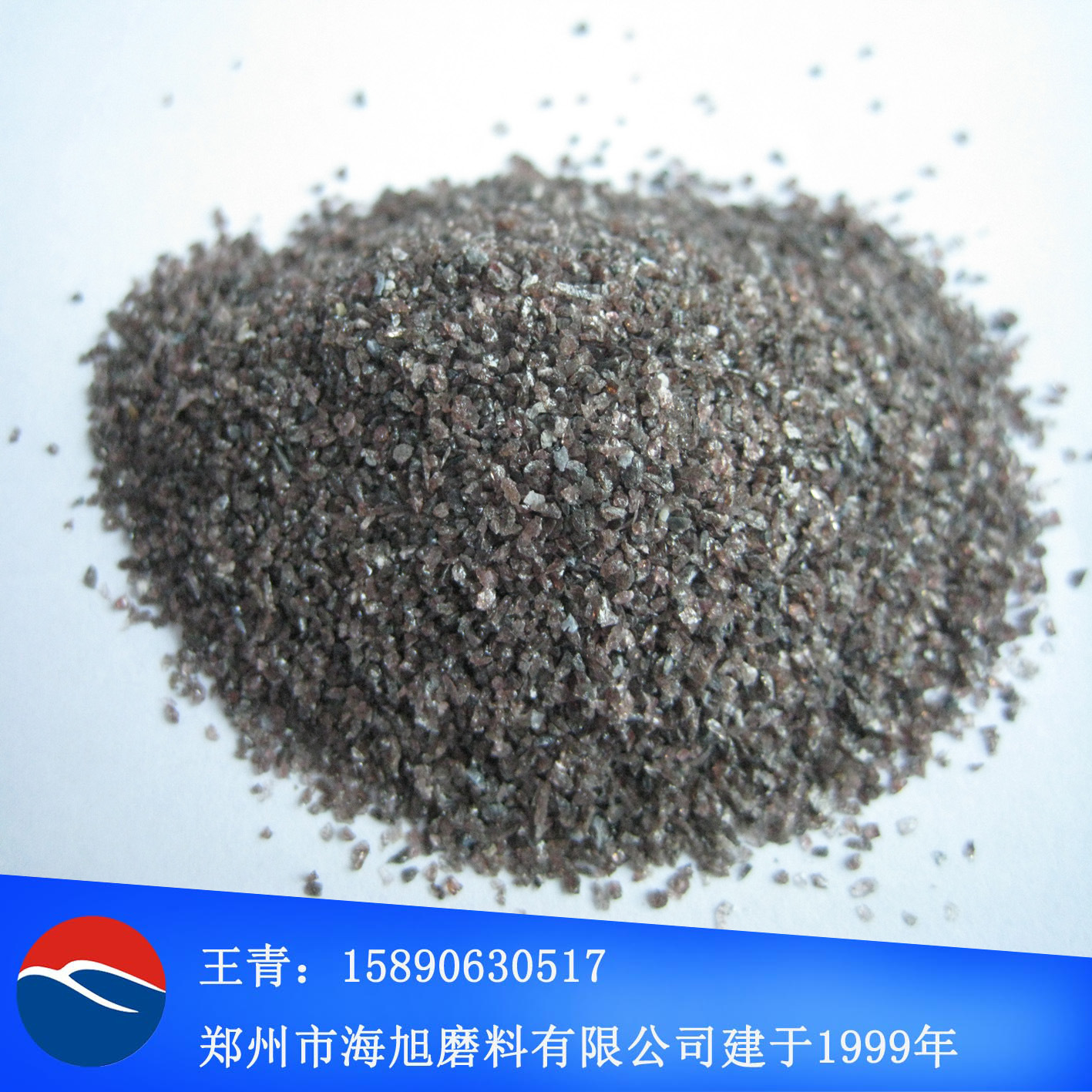

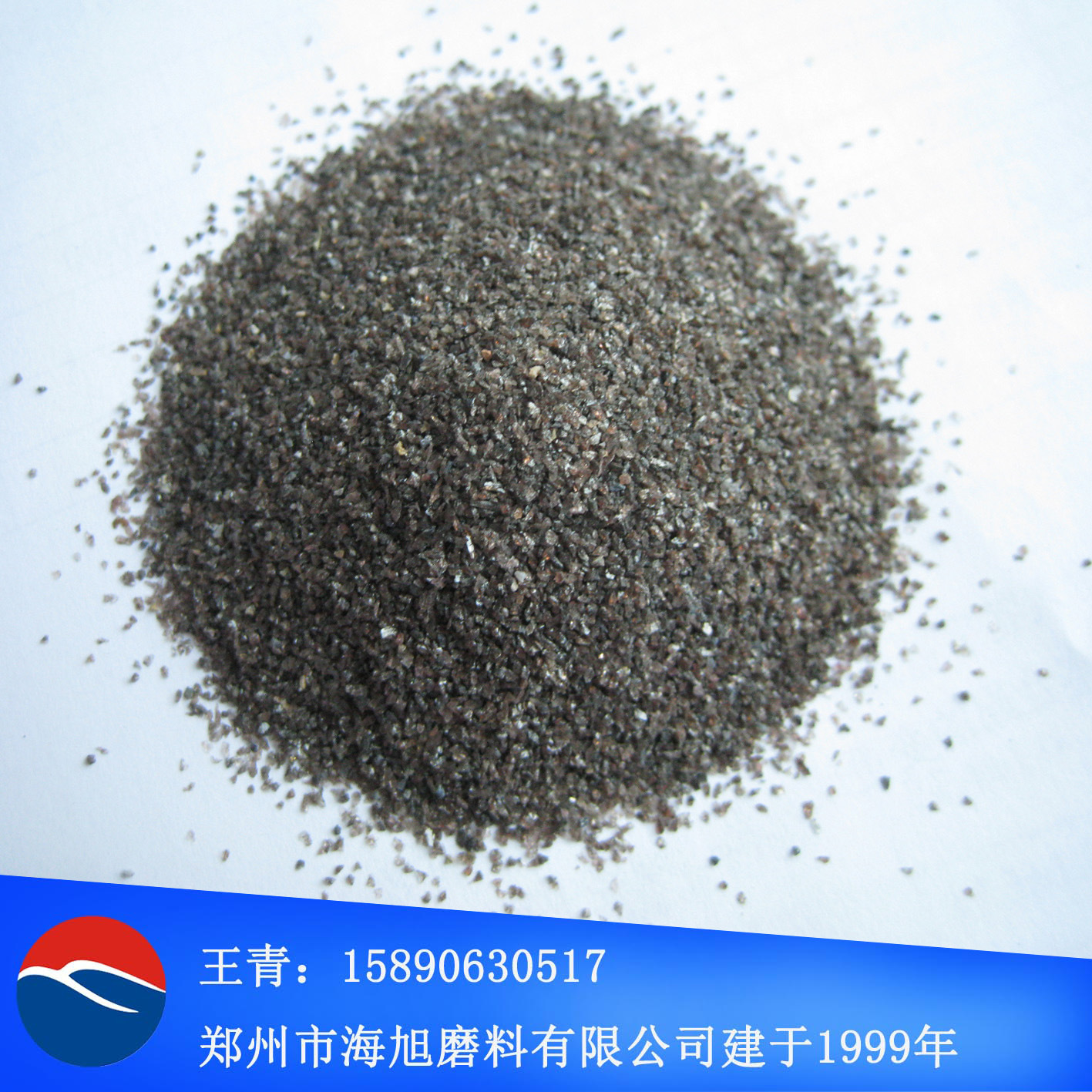

粒度砂 |

F8, F10, F12, F14, F16, F20, F22, F24, F30, F36, F40, F46, F54, F60, F70, F80, F90, F100, F120, F150, F180, F220 8#,10#,12#,14#,16#,20#,22#,24#,30#,36#,40#,46#,54#60#,70#,80#,90#,100#,120#,150#,180#,220# 8目, 10目, 12目,14目,16目,20目,22目,24目,30目,36目,40目,46目,54目, 60目,70目,80目,90目, 100目,120目,150目,180目,220目,240目,320目,400目,600目,800目等 |

|

微粉 |

W63, W50, W40, W28, W20, W14, W10, W7, W5, W3.5, W2.5, W1.5, W1, W0.5 F230, F240, F280, F320, F360, F400, F500,F600, F800, F1000, F1200, F1500 JIS240-JIS12000 |

|

可提供标准 |

F标,欧标,JIS日本标,*等 |

三,主要物理特性Main Physical Properties

|

颜色COLOR |

棕色,棕红色BROWN,RED BROWN |

|

莫氏硬度MOHS HARDNESS |

9.0 |

|

堆积密度BULK DENSITY |

1.75-1.95g/cm3 |

|

比重SPECIFIC GRAVITY |

3.6-3.9g/cm3 |

|

体积密度volume density |

3.6-3.9g/cm3 |

|

熔点melting point |

2250°C |

|

使用温度maximum service temperature |

1900°C |

四、用于磨料,喷砂,研磨,抛光Used for abrasives,blastinrinding

|

属性properties

规格Type |

粒度砂Grains |

||

|

8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# |

|||

|

保证值Guarantee Value |

典型值Typical Value |

||

|

化学成分 Chemical Comition |

Al2O3 |

≥95 |

95.65 |

|

SiO2 |

≤1.5 |

1.04 |

|

|

Fe2O3 |

≤0.5 |

0.14 |

|

|

TiO2 |

≤3 |

2.2 |

五,用途Application

1.用于铝型材,铜型材玻璃,水洗牛仔服模具等的“”喷砂

environmental blasting for aluminium profile/Copper material of glass/water to wash jeans

2.应用于显像管、玻璃、单晶硅、镜片、玉器等的自由研磨

Grinding for kinescope/glas*onocrystalline silicon/lens/jadeware

3.可作为修筑高速公路路面、飞机跑道、码头、停车场、工业地坪、体育场地等*材料

Abrasion-proof material for expressway/airstrip/dock/parking lot/stadium

4.固结磨具和涂覆(涂附磨具)磨具Bonded abrasives and Coated abrasives

5.表面处理 Surface preparation and finishing

6.热喷涂/等离子喷涂Thermal Spraying (Pla*a Spraying)

7.表面处理 Surface preparation and finishing

8.耐火材料,陶瓷Super Refractories, Ceramics and Tiles

9.抛光和微分子喷砂Lapping & Micro-blasting applicati*