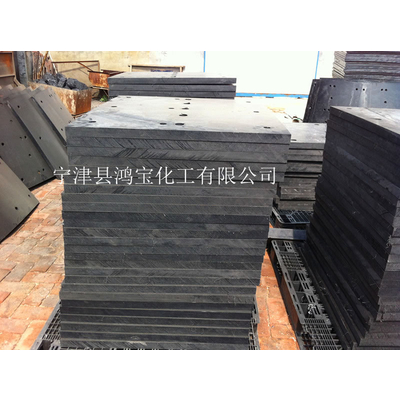

厂家*加工* 耐冲击*压闸门垫块

¥23.99元/千克

中国 山东 德州 宁津县

来电请说明在第一枪看到,谢谢!

产品属性

- 型号:

- 各种尺寸均能生产定做

- 品牌/厂家:

- 其他

- 类型:

- 正牌料

- 用途级别:

- 膜压级

- 牌号:

- HB

- 产地:

- 德州鸿宝

- 密度:

- 0.98

- 拉伸强度:

- 2900

- 断裂伸长率:

- 350

- 成型收缩率:

- 0.1

- 热变形温度:

- 85

- 阻燃等级:

- 优良

工程塑料合金:塑料合金是利用物理共混或化学接枝的方法,对现有的塑料进行改性,使之实现*化、功能化、*化。它能****或****现有塑料的性能并降低成本,已成为塑料工业中****为活跃的领域之一,并且增长十分迅速。据*预测,随着经济的发展,2018年前后世界塑料合金需求量将达到350万吨。

Engineering plastic alloy: plastic alloy is using the method of physical blending or chemical grafting, the existing plastic wa*odified to achieve high performance, functional specialization. It can improve the performance of the existing plastic and reduce the cost, has become one of the most active areas in the plastics industry, and growth very quickly. Experts predict that with the developme*f economy, before and after 2018 the world plastic alloy demand will reach 3 million 500 thousand t*.

目前,通用塑料合金,如PVC(聚*)、PE(聚乙烯)、PP(聚*)、PS(聚*)等虽然仍有着广泛的使用价值,但因其生产技术被普遍掌握,国外一些大公司专门供应的多是附加值较高的工程塑料合金品种。工程塑料合金泛指工程塑料(树脂)的共混物,主要包括以PC(聚碳酸酯)、PBT(聚对苯二甲酸*酯)、PA(尼龙)、POM(聚甲醛)、PPO(聚苯醚)、等塑料为主体的共混体系,以及在某些场合常被归属于工程塑料的ABS(?丁二烯?*共聚物)树脂改性材料。****近十几年,世界塑料合金的年均需求增长率为10%左右,而其中附加值高的工程塑料合金的增长率更高达15%左右,成为跨国公司积****开发的品种。在美国、欧洲、日本已实现工业化的塑料合金品种中,工程塑料合金占绝大多数,合金化已成为当前工程塑料改性的主要方法。随着我国经济的持续高速发展,今后几年我国塑料合金市场需求潜力巨大,尤其是电子通讯、汽车、建筑业的高速增长,将拉动我国工程塑料合金业快速发展。

At present, universal plastic alloys, such as PVC (polyvinyl chloride) (PVC) and polystyrene (PP), are still widely used, but they h*e been widely mastered because of their production technology.Some large foreign companies are specialized in the supply of high added-value engineering plastic alloy varieties.Engineering plastics alloys generally refer to the blends of engineering plastics (resins), which mainly c*ist of a blend system c*isting mainly of PC- (polybutylene terephthalate) (PBT) (polybutylene terephthalate) (PAA) (polyformaldehyde (PPO)) (polytetrafluoroethylene (PTFE) and other plastics). And ABS (acrylonitrile), which is often assigned to engineering plastics in some cases.Butadiene?Styrene copolymer) resin modified material.In the last ten years, the annual demand growth rate of plastic alloys in the world is about 10%, and the growth rate of engineering plastics alloys with the highest added value is about 15%, which has become*ariety actively developed by multinational corporati*.In America, Europe and Japan, engineering plastics alloys account for the majority of all kinds of plastic alloys, and alloying has become the main method of modification of engineering plastics.With the sustained and rapid developme*f China's economy, the marke*mand for plastic alloys in China has great potential in the next few years. In 2002, the rapid growth of electronic communication, automobile and c*truction industry will promote the rapid developme*f engineering plastic alloy industry in China.

Engineering plastic alloy: plastic alloy is using the method of physical blending or chemical grafting, the existing plastic wa*odified to achieve high performance, functional specialization. It can improve the performance of the existing plastic and reduce the cost, has become one of the most active areas in the plastics industry, and growth very quickly. Experts predict that with the developme*f economy, before and after 2018 the world plastic alloy demand will reach 3 million 500 thousand t*.

目前,通用塑料合金,如PVC(聚*)、PE(聚乙烯)、PP(聚*)、PS(聚*)等虽然仍有着广泛的使用价值,但因其生产技术被普遍掌握,国外一些大公司专门供应的多是附加值较高的工程塑料合金品种。工程塑料合金泛指工程塑料(树脂)的共混物,主要包括以PC(聚碳酸酯)、PBT(聚对苯二甲酸*酯)、PA(尼龙)、POM(聚甲醛)、PPO(聚苯醚)、等塑料为主体的共混体系,以及在某些场合常被归属于工程塑料的ABS(?丁二烯?*共聚物)树脂改性材料。****近十几年,世界塑料合金的年均需求增长率为10%左右,而其中附加值高的工程塑料合金的增长率更高达15%左右,成为跨国公司积****开发的品种。在美国、欧洲、日本已实现工业化的塑料合金品种中,工程塑料合金占绝大多数,合金化已成为当前工程塑料改性的主要方法。随着我国经济的持续高速发展,今后几年我国塑料合金市场需求潜力巨大,尤其是电子通讯、汽车、建筑业的高速增长,将拉动我国工程塑料合金业快速发展。

At present, universal plastic alloys, such as PVC (polyvinyl chloride) (PVC) and polystyrene (PP), are still widely used, but they h*e been widely mastered because of their production technology.Some large foreign companies are specialized in the supply of high added-value engineering plastic alloy varieties.Engineering plastics alloys generally refer to the blends of engineering plastics (resins), which mainly c*ist of a blend system c*isting mainly of PC- (polybutylene terephthalate) (PBT) (polybutylene terephthalate) (PAA) (polyformaldehyde (PPO)) (polytetrafluoroethylene (PTFE) and other plastics). And ABS (acrylonitrile), which is often assigned to engineering plastics in some cases.Butadiene?Styrene copolymer) resin modified material.In the last ten years, the annual demand growth rate of plastic alloys in the world is about 10%, and the growth rate of engineering plastics alloys with the highest added value is about 15%, which has become*ariety actively developed by multinational corporati*.In America, Europe and Japan, engineering plastics alloys account for the majority of all kinds of plastic alloys, and alloying has become the main method of modification of engineering plastics.With the sustained and rapid developme*f China's economy, the marke*mand for plastic alloys in China has great potential in the next few years. In 2002, the rapid growth of electronic communication, automobile and c*truction industry will promote the rapid developme*f engineering plastic alloy industry in China.

内容声明:第一枪网为第三方互联网信息服务提供者,第一枪(含网站、微信、百家号等)所展示的产品/服务的标题、价格、详情等信息内容系由卖家发布,其真实性、准确性和合法性均由卖家负责,第一枪网概不负责,亦不负任何法律责任。第一枪网提醒您选择产品/服务前注意谨慎核实,如您对产品/服务的标题、价格、详情等任何信息有任何疑问的,请与卖家沟通确认;如您发现有任何违法/侵权信息,请立即向第一枪网举报并提供有效线索至b2b@dyq.cn