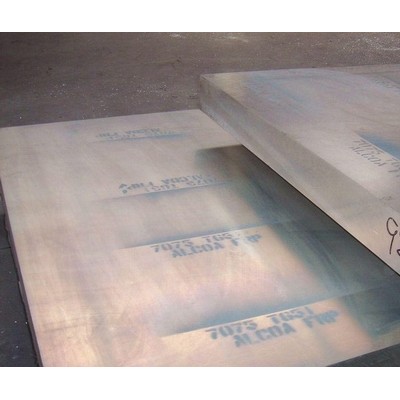

2017铝板价格,2017铝板规格,2017铝板供应商

产品属性

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 材料名称

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 牌号:<*n lang="EN-US">2017<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">铝合金

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 材料简介

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">2017<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">铝板是****个获得工业应用的<*n lang="EN-US">2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">系合金,具有很高的强度和良好的切削加工性能,但耐腐蚀性较差。<*n lang="EN-US">2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">系列铝板的特点是硬度较高,其中以铜原属含量****,大概在<*n lang="EN-US">3-5%<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">左右。

<*n lang="EN-US">2<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">系列铝板属于航空铝材,目前在常规工业中不常应用。我国目前生产<*n lang="EN-US">2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">系列铝板的厂家较少。质量还无法与国外相比。目前进口的铝板主要是由韩国和德国生产企业提供。随着我国航空航天事业的发展,<*n lang="EN-US">2<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">系列的铝板生产技术将进一步****。

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">材料特性

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">2017<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">为铝-铜-镁系中的典型硬铝合金,其成份比较合理,综合性能较好。很多*都生产这个合金,是硬铝中用量****的。该合金的特点是:强度高,有一定的耐热性,可用作<*n lang="EN-US">150°C<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">以下的工作零件。温度高于<*n lang="EN-US">125°C<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">,<*n lang="EN-US">2017<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">合金的强度比<*n lang="EN-US">7075<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">合金的还高。热状态、退火和新淬火状态下成形性能都比较好,热处理强化效果显著,但热处理工艺要求严格。*蚀性较差,但用纯铝包覆可以得到有效保护<*n lang="EN-US">;<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">焊接时易产生裂纹,但采用特殊工艺可以焊接,也可以铆接。广泛用于飞机结构、铆钉、卡车轮毂、螺旋桨元件及其他种种结构件。

<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">材料用途

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> <*n lang="EN-US">2017<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">铝板通常应用于铆钉、通用机械零件、飞机、船舶、交通、建筑结构件、运输工具结构件、螺旋桨元件及配件等。

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">编辑本段物理性能

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">化学成分

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">铁<*n lang="EN-US">(Fe)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.70<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">, <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">锰<*n lang="EN-US">(Mn)<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">0.40<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">~<*n lang="EN-US">1.0 <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">, <*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">镁<*n lang="EN-US">(Mg)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">0.4<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">~<*n lang="EN-US">0.80 <*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">硅<*n lang="EN-US">(Si)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">0.20<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">~<*n lang="EN-US">0.80<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">, <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">锌<*n lang="EN-US">(Zn)<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">0.25 <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">,

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">钛<*n lang="EN-US">(Ti)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">:<*n lang="EN-US">0.15 <*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">铬<*n lang="EN-US">(Cr)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">0.10<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">, <*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">铜<*n lang="EN-US">(Cu)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">3.5<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">~<*n lang="EN-US">4.5<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">, <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">铝<*n lang="EN-US">(Al)<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">余量 <*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">单个:<*n lang="EN-US">0.05

<*n lang="EN-US">2017<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">可分为的状态

<*n lang="EN-US">O<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、<*n lang="EN-US">T4

<*n lang="EN-US">O<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、<*n lang="EN-US">T4<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T4510<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T4511

<*n lang="EN-US">O<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、<*n lang="EN-US">H13<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T4<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T451

<*n lang="EN-US">O<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、<*n lang="EN-US">H13<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T4<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">、<*n lang="EN-US">T451

<*n lang="EN-US">T4

<*n lang="EN-US">F<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">、<*n lang="EN-US">T4

<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">力学性能

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> *拉强度<*n lang="EN-US"> σb (MPa)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">215<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">~<*n lang="EN-US">355

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 伸长率<*n lang="EN-US"> δ10 (<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">%<*n lang="EN-US">)<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">:<*n lang="EN-US">12<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">~<*n lang="EN-US">17

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 固溶处理温度:<*n lang="EN-US">500<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">℃~<*n lang="EN-US">510<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">℃<*n lang="EN-US">.

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 冷加工材料退火范围:<*n lang="EN-US">340<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">℃~<*n lang="EN-US">350<*n style="font-family: 宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">℃<*n lang="EN-US">.

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 热处理后材料退火温度:<*n lang="EN-US">415<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman";mso-hansi-font-family: "Times New Roman"">℃。

<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">相关技术标准

<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman""> 铝板带*标准<*n lang="EN-US"> (GB/T 3880-2006)<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">,适用于铝合金板带材料的统一标准。

<*n style="font-family:宋体;mso-ascii-font-family: "Times New Roman";mso-hansi-font-family:"Times New Roman"">热处理工艺

<*n style="font-family:宋体; mso-ascii-font-family:"Times New Roman";mso-hansi-font-family:"Times New Roman"">状态、退火和新淬火状态下成形性能都比较好,热处理强化效果显著,但热处理工艺要求严格。*蚀性较差,但用纯铝包覆可以得到有效保护<*n lang="EN-US">;<*n style="font-family:宋体;mso-ascii-font-family:"Times New Roman"; mso-hansi-font-family:"Times New Roman"">焊接时易产生裂纹,但采用特殊工艺可以焊接,也可以铆接。

<*n lang="EN-US">