UV解胶机 UV Tape脱胶机 半导体UV解胶机

产品属性

- 品牌:

- 其他

- 型号:

- UV150

深圳市德胜兴电子有限公司提供现货库存UV解胶机

什么是UV解胶机?

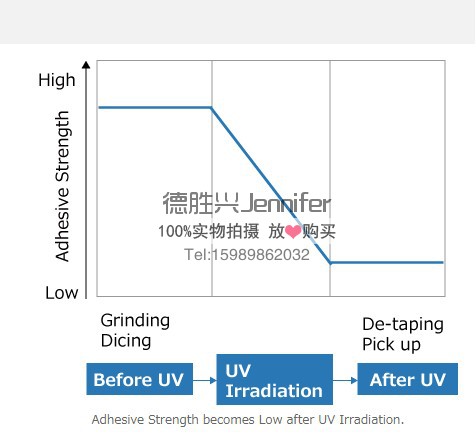

在半导体芯片生产工艺中,芯片划片之前,要将晶圆片用划片胶膜固定在框架上,在划片工艺完成后,用UV光对固定胶膜进行照射使UV胶膜粘性固化硬化,以降低划片固定膜的粘性,以便后续封装工序的顺利生产。换句话讲,UV胶带具有很强的粘合强度,在晶片研磨工艺或晶片切割工艺期间,胶带牢固地粘住晶片。当紫外线照射时,粘合强度变低。因此,在紫外线照射后晶圆或芯片很容易从粘胶带上面剥离脱落。UV解胶机解决了晶圆、玻璃和陶瓷切割工艺的解胶工序,适用行业目前不仅局限于半导体封装行业,还适用于光学镜头、LED、IC、半导体、集成电路板、移动硬盘等半导体材料UV膜脱胶使用。现有技术中的UV解胶机多采用UV*灯,而本身具有高热量排放的*灯光源容易对热敏感材料照成损坏,且效率低,质量标准难以准确把控,不适合芯片等高精密 器件的照射。深圳市德胜兴电子有限公司采用的环境友好型低温LED UV光源解胶机,轻易完成UV膜 脱膜工艺,且不损伤晶圆,****大满足生产需求。

用途:适用于光学镜头、LED、IC、半导体、集成电路板、移动硬盘等半导体材料,玻璃滤光片等UV膜脱胶,UV胶带脱胶使用。UV解胶机是一种UV膜和切割膜胶带粘性降低和粘性解除的全自动化解胶设备。晶圆、玻璃等料件,使用UV TAPE贴胶于 8寸,12寸,15寸的支架治具解胶装置,具有****率的解胶能力,可快速的降低UV TAPE贴于料件的黏性。

UV解胶机特点:

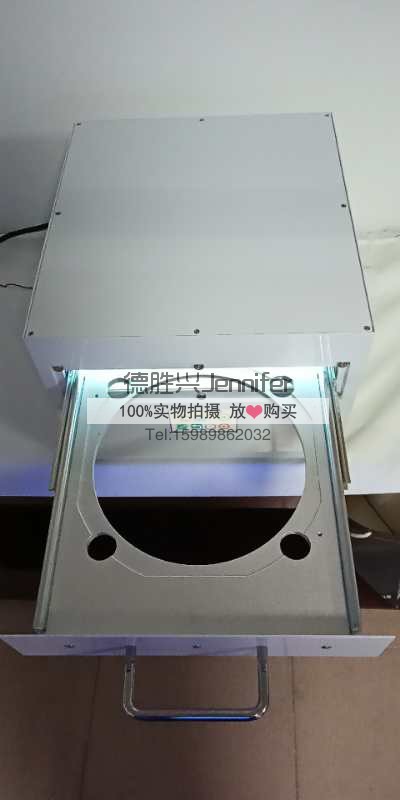

1) 机身小巧,适合6/8/10/12寸芯片整片照射使用

2) 时间和亮度可调,触屏操作,简单方便

3)自下而上照射, 方便放置晶圆

4) LED冷光源,环保产品,具有温度低、*均匀、结构紧凑、能耗小、是半导体行业的理想机型,且低温对热敏材料无损害

5) 使用寿命比普通*灯寿命长10倍以上,连续使用寿命15000-30000H。

6) 零维护成本,长期工作无需更换照射光源零件

7) 封闭式光源设计,无紫外线侧漏,对*无损伤

参数

|

序号 |

内 容 |

参 数 |

|

1 |

适用晶圆大小 |

6” 8”10” 12‘’ (多种规格可选)6寸 8寸 10寸 12寸 |

|

2 |

出光面积 |

Φ150mm, Φ200mm, Φ300mm |

|

3 |

额定电压 |

AC 110/220V |

|

4 |

频率 |

50/60HZ |

|

5 |

额定功率 |

350-900W |

|

6 |

UV灯波长 |

365nm-415nm可选, 常规为365nm |

|

7 |

外形尺寸(长*宽*高) |

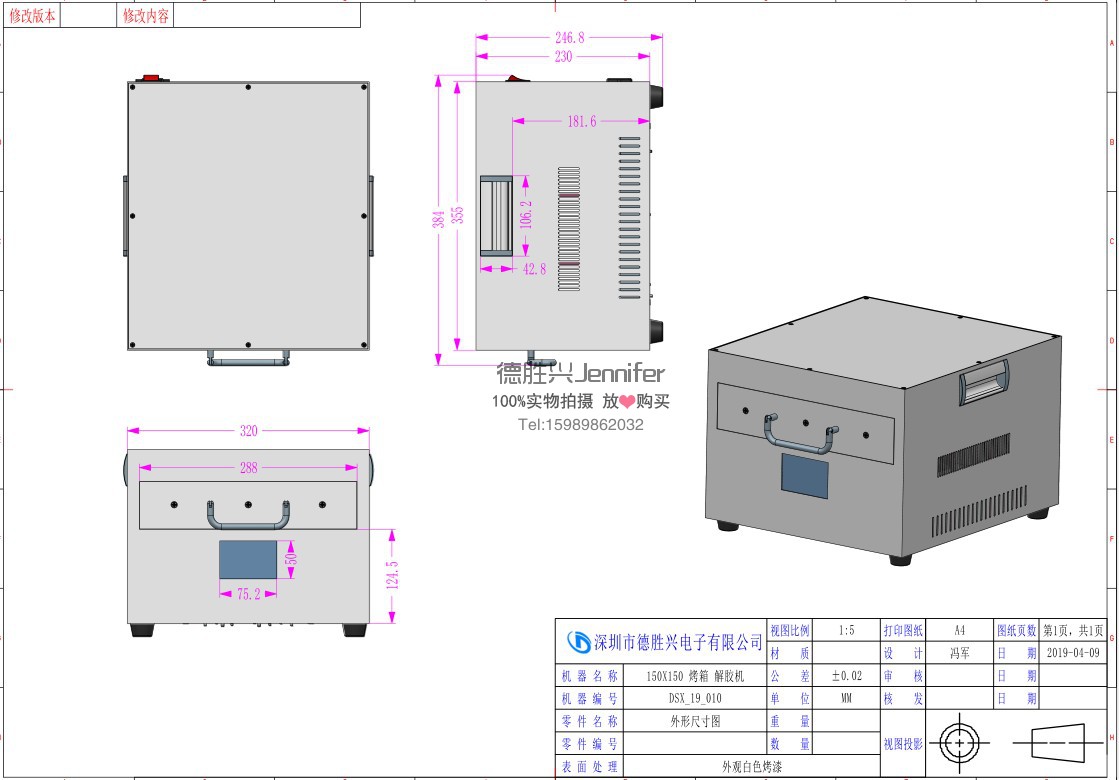

320mm×384mm×247mm 尺寸可定制 |

|

8 |

机器重量 |

6.5kg |

|

9 |

胶膜类型 |

UV膜 各种UV Tape |

|

10 |

胶膜厚度 |

0.15~2mm |

|

11 |

照射方向 |

自下而上照射 |

|

12 |

操作方式 |

触屏操作 |

|

13 |

计时器设定时间 |

不限 (单位:S)时间可调 |

|

14 |

解胶完成时间 |

以UV胶带特性而定(可****短 5秒) |

|

15 |

照射强度设定 |

20% ~ 100% 亮度可调 |

|

16 |

制具配件 |

按客户要求定制 默认5.9英寸 |

UV curing systems process wafers up to 300mm, applying even UV irradiation over the entire wafer surface and providing safe, reliable ozone-free UVA irradiation. Napolun UV curing systems provide optimal, co*olled UV ex*ure for efficient curing using safe, ozone-free UVA irradiation for reliable, worry-free operation. Single-frame or cassette-loader models select the model that's right for you. Napolun UV curing systems provide can increase yields when dicing on UV adhesive tape. Napolun provides a wide range of manual and fully automatic systems to meet all production throughput requirements.

The great advantages of the Napolun UV curing technology is in the special dedicated design for curing of wafer*ounted on dicing frames. The UV tape is used in the semiconductor assembly process to *ition the silicon wafer on the dicing frame while dicing. The adhesi*trength between irradiated UV dicing tape and silicon i*uch higher while dicing the wafers, and much lower compared to non UV dicing tape (i.e. “sticky tape” or “blue tape” or "Nitto tape"). Thus, the adhesive force allow safer and faster cutting of the wafer, and after the wafer is cut, a safer and faster pick-up process from the cured tape. Napolun Systems are fully compliant with all types of tape manufacturers: Furukawa, Nitto, Lintec and others and can process all types of frames: Disco, K&S and TSK.

Our UV Curing Systems offer inexpensive soluti* for the curing of UV films in easy-to-use benchtop package.