万鑫GH22-200-60S卧式齿轮减速马达

产品属性

- 减速比:

- 60

- 安装方式:

- 卧式

- 级数:

- 单级

- 齿面硬度:

- 硬齿面

- 布局形式:

- 同轴式

- 品牌:

- 其他

- 加工定制:

- 是

- 型号:

- GH22-200-60S

- 额定功率:

- 100W

- 额定电压:

- 220/380

- 额定电流:

- 0.5

- 额定转速:

- 1400

- 额定转矩:

- 1.5

- 效率:

- 99

- 绝缘等级:

- F

- 防护等级:

- F

- 产品认证:

- CE

- 外形尺寸:

- 多规格

- 重量:

- 6.7KG

万鑫齿轮减速马达部分型号:GH18-75-5S GH18-75-10S GH18-75-15S GH18-75-20S GH18-75-50S GH18-75-60S GH18-75-100S GH22-75-200S GH18-100-3S GH18-100-5S GH18-100-10S GH18-100-20S GH18-100-50S GH22-100-60S GH22-100-80S GH22-100-100S GH22-100-150SGH22-100-180S GH22-100-200S GH28-100-1800S GH18-2003S GH18-200-5S GH18-200-10S

GH22-200-15S GH22-200-20S GH22-200-30S GH22-200-40S

GH22-200-60S GH22-200-90S GH28-200-100S GH28-200-150S

GH28-200-200S GH32-200-300S GH32-200-500S GH32-200-1800S

GH22-400-3S GH22-400-5S GH22-400-7.5S GH22-400-10S GH28-400-15S GH28-400-20S GH28-400-25S GH28-400-30S GH28-400-40S GH28-400-50S GH28-400-60S GH28-400-80S GH32-400-100S

GH32-400-145S GH32-400-150S GH32-400-200S GH40-400-500S

GH40-400-1800S GH40-400-1500S GH28-750-3S GH28-750-5S GH28-750-10S GH28-750-15S GH28-750-20S GH28-750-S5S GH32-750-30S GH32-750-50S GH32-750-60S GH32-750-100S GH40-750-125S GH40-750-150S GH40-750-180S GH40-750-200S GH50-750-300S GH50-750-500S GH50--750-1000S GH50-750-1500S GH50-750-1800S GH32-1500-3S GH32-1500-5S GH32-1500-7.5S GH32-1500-10S GH32-1500-15S GH32-1500-20S GH32-1500-25S GH40-1500-30S GH40-1500-40S GH40-1500-50S GH40-1500-60S GH30-1500-80S GH40-1500-100S GH40-1500-120S GH50-1500-125S GH50-1500-150S GH50-1500-180S GH50-1500-200S GH40-2200-3S GH40-2200-5S GH40-2200-7.5S GH40-2200-10S GH40-2200-15S GH40-2200-20S GH40-2200-25S GH40-2200-30S GH40-2200-40S GH40-2200-50S GH40-2200-60S GH50-2200-100S GH50-2200-125S GH50-2200-150S GH50-2200-180S GH50-2200-200S GH40-3700-3S GH40-3700-5S GH40-3700-7.5S GH40-3700-10S GH40-3700-15S GH40-3700-20S GH40-3700-25S GH50-3700-30S GH50-3700-50S GH50-3700-60S GH50-3700-80S GH50-3700-100S GH50-3700-150S GH50-3700-180S GH50-3700-200S

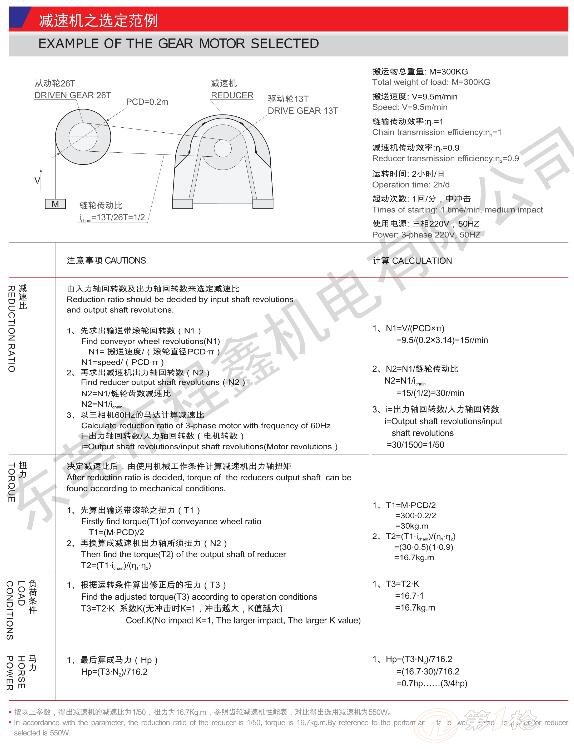

减速机的正确安装

正确的安装,使用和维护减速机,是保证机械设备正常运行的重要环节。 因此,在您安装齿轮减速机时,请务必严格按照下面的安装使用相关事项,认真地装配和使用。

1步是安装前确认电机和减速机是否完好无损,并且严格检查电机与减速机相连接的各部位尺寸是否匹配,这里是电机的凸台、输入轴与减速机凹槽等尺寸及配合公差。

第二步是旋下减速机法兰外侧防尘孔上的螺钉,调整PCS系统夹紧环使其侧孔与防尘孔对齐,插入内六角旋紧。之后,取走电机轴键。

第三步是将电机与减速机自然连接。连接时必须保证减速机输出轴与电机输入轴同心度一致,且二者外侧法兰平行。如同心度不一致,会导致电机轴折断或减速机齿轮磨损。

另外,在安装时,严禁用铁锤等击打,防止轴向力或径向力过大损坏轴承或齿轮。一定要将安装螺栓旋紧之后再旋紧紧力螺栓。安装前,将电机输入轴、凸台及减速机连接部位的防锈油或锌钠水擦拭净。其目的是保证连接的紧密性及运转的灵活性,并且防止不必要的磨损。 在电机与减速机连接前,请先将电机轴键槽与紧力螺栓垂直。为保证受力均匀,请先将任意对角位置的安装螺栓旋上,但不要旋紧,再旋上另外两个对角位置的安装螺栓*逐个旋紧四个安装螺栓。 *,旋紧紧力螺栓。所有紧力螺栓均需用力矩扳手按标明的固定扭力矩数据进行固定和检查。 直角减速机的相关数据与同型号直线减速机并不完全相同,还请使用者注意。 *减速机与机械设备间的正确安装类同减速机与驱动电机间的正确安装。关键是要必须保证减速机输出轴与所驱动部分轴同心度一致。

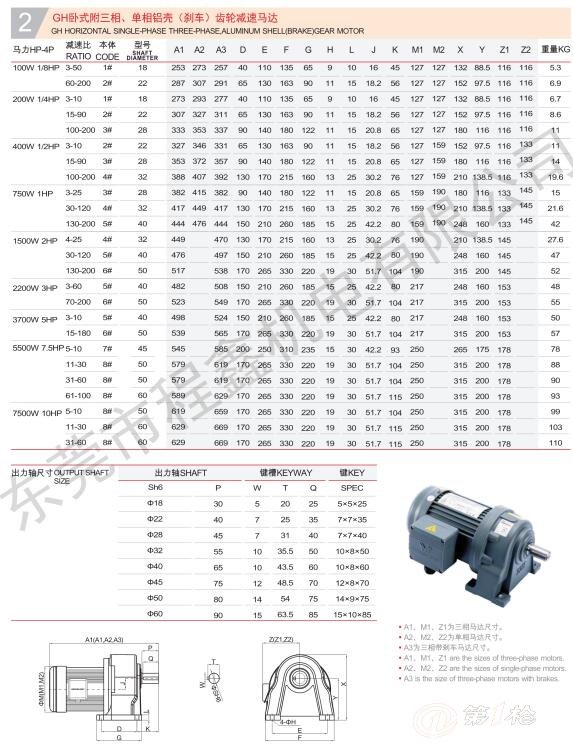

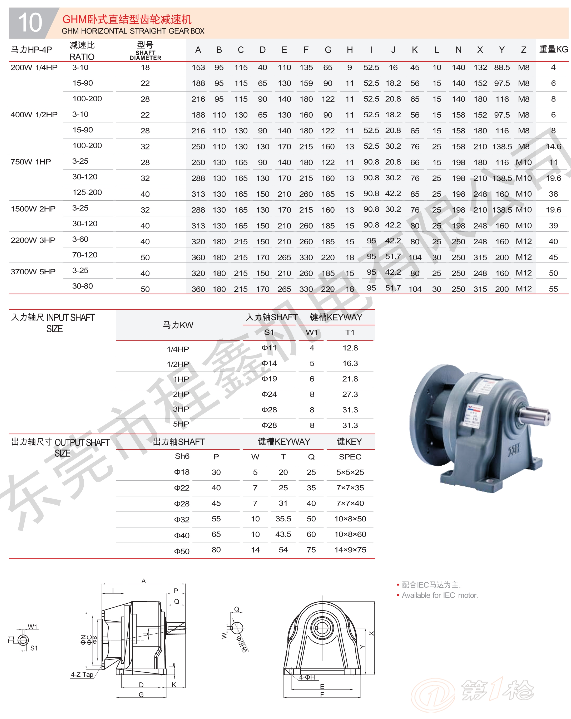

齿轮减速马达的型号

齿轮减速电机分为卧式和立式,分别用GH和GV表示。

框号有18、22、28、32、40、45、50、55等,表示不同的减速箱框号,数字代表出力轴径。

电机功率有0.075KW,0.1KW,0.2KW,0.4KW,0.55KW,0.75KW,1.1KW,1.5KW,2.2KW,3.7KW,5.5KW等

减速比范围:3-18000比

频率分三相和单相,S代表三相,A代表单相。B表示刹车。